Oh trust me i won't :biggrin::biggrin:

George, I was hoping to leave it as large as possible for a winged bowl or platter

Fair enough Keithkarl2007, that was always another possibility...!

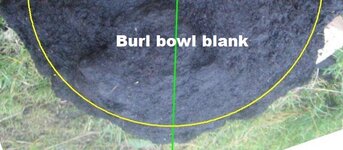

In that case, and if the proportions are right based on the size of the bricks next to it, I would say that the burl is about 15" at is wider point, so you should have about 12" of clean cut, everything going right, and about 8" of depth. This will always be a one shot attempt, if you want to utilize most of the burl as a bowl so, it's worth a go, for sure.

I'm attaching your edited pic, with some drawings of how I would cut it for a bowl, it may help you...!

Another important thing is to try remove the bowl's "guts" before if will become shavings, you will be able to make either a smaller bowl or a few pen blanks, just to name a few! If you don't have a proper "bowl saving" cutter, is easy enough to do it with a good partition gauge (also pics attached).

Your type burl is no longer "green" but, you can process it as if it was, just to be on the safe side, this include the turning of the burl, with a more chances for success to rough turn it as you would normally do with green timber, leaving about 1" thickness all around to give you a safe margin to re-turn it later on.

I would certainly give it a couple of coats of a good timber stabilizer , as soon as it would come off the lathe, for safety and then put it a side to dry for a few weeks. Obviously, whatever the drying time I mention here is based on the principal that we have about 25C on average, so cooler locations will require a little more time, unless the timber is dried artificially!

Don't do the mistake a friend of mine did, he loved Olive wood that much that the day he had the opportunity to get a large block from a olive butt/root, he got home and cleaned that root to almost perfection (you will never get all the dirt/stones/sand, etc.) and store it in the driest and safest place he had in his large shed. He would daily go to that shed to do stuff, mainly turning and other wood objects, and every day he looked at it and wished he could turn it.

Not long after we met, I visit him for a day of wood-turning (boys day, sort of thing...!) at his shed, and as I enter the shed, my eyes nearly come out of my sockets when I looked down under a large shelve and saw on top of a timber pallet, this humongous chunk of olive, that I calculate to be about 100kg+. After a few questions of what in a heck?, we admitted to me, and later on confirmed by his wife that, the olive root has been there "waiting" to dry for 25 years, yes twenty five years...!

This poor guy din't had a clue what to do with it when he got it, someone told him that olive wood take over 20 years to dry so, he just patiently waited and looked and waited everyday. He got to a point that the 20 years were due but, he completely got stressed out and panicking about the possibility to bugger the whole thing over, a few years before the time was over...! poor guy, he was so scared to touch it that, nearly every day, as he modestly admitted, he would awake up in the morning thinking, yeah, today is the day, have his breakfast and walk to his shed for his "adventure" but as soon as he would see it, he would just go the jelly and give up.

That same day, and after a table conversation back in the house with his wife at the same table over a nice coup of coffee, I convinced him to wait no longer and stop him feeling sick about it, in secrecy for all those years.

Fortunately for me, he had his work shop set-up beautifully, wasn't much he didn't had there in regards to tools and machinery to work with timber.

The rest is History really, I reckon he got a big load off his back and for the way I saw it, that weight was identical to the root, I'm sure!

I got a small piece of it as a special "momento" of the occasion, it still has been untouched since as a reminder...! I can also say that the number of pieces he turned out of that root, were enough to keep him in his dream world for nearly 6 months...!:biggrin:

I hope this info can be of some help to you!

Cheers

George

:biggrin:

:biggrin: