watch_art

Member

OKay - I ordered some custom PR from Slabs, and they delivered - boy did they deliver! This stuff is PERFECT. Exactly what I wanted. Beautiful!

But... sigh... the two parts don't want to stick together.

We're working on solutions for later orders (and yes there will be more orders) but for now we're thinking to just soak it with CA as I turn it so it holds together. I had a bit of a blow out last night as I was turning a barrel down. There wasn't enough of the poured PR holding things together. THis stuff would be perfect on a component pen, and I may have to use these for that, but eventually I'm going to win. You hear me!!? :biggrin:

Here are some pics of this lovely stuff. I was wanting something to replicate an old Waterman celluloid which they called turquoise. Used it on their Patrician.

turquoise by snennewton, on Flickr

007 by snennewton, on Flickr

008 by snennewton, on Flickr

A finished section. It all held together fine except for the threads, which I covered in super glue and then threaded. It's good now, though. I wonder how it would stand up to some use and abuse?

001 (2) by snennewton, on Flickr

002 by snennewton, on Flickr

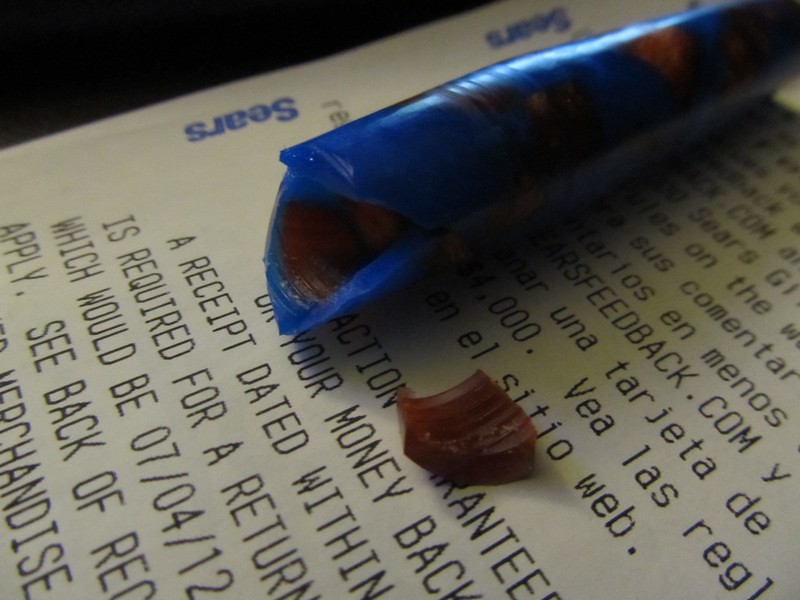

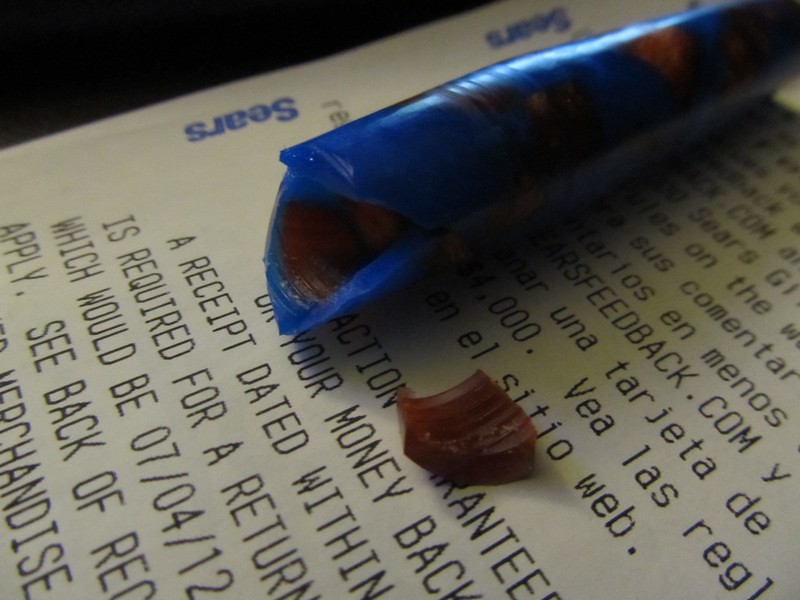

And then a sad sad bit of news. I was REALLY tired when turning this - I may have been pushing on it harder than I realize. I had started seeing double by this point - so maybe it's my fault?

005 by snennewton, on Flickr

Man, I hope so. It's SO PRETTY!

001 by snennewton, on Flickr

Thoughts?

But... sigh... the two parts don't want to stick together.

We're working on solutions for later orders (and yes there will be more orders) but for now we're thinking to just soak it with CA as I turn it so it holds together. I had a bit of a blow out last night as I was turning a barrel down. There wasn't enough of the poured PR holding things together. THis stuff would be perfect on a component pen, and I may have to use these for that, but eventually I'm going to win. You hear me!!? :biggrin:

Here are some pics of this lovely stuff. I was wanting something to replicate an old Waterman celluloid which they called turquoise. Used it on their Patrician.

turquoise by snennewton, on Flickr

007 by snennewton, on Flickr

008 by snennewton, on Flickr

A finished section. It all held together fine except for the threads, which I covered in super glue and then threaded. It's good now, though. I wonder how it would stand up to some use and abuse?

001 (2) by snennewton, on Flickr

002 by snennewton, on Flickr

And then a sad sad bit of news. I was REALLY tired when turning this - I may have been pushing on it harder than I realize. I had started seeing double by this point - so maybe it's my fault?

005 by snennewton, on Flickr

Man, I hope so. It's SO PRETTY!

001 by snennewton, on Flickr

Thoughts?