Hi all,

I recently made a group of long click pens,and even after measuring with calipers I still ended up with a razor sharp edge you can feel at the nib/barrel transition.It really bugs me if I can feel it.I guess I was in a hurry making them,only to scrutinize them later at home.

One had a migrating clip too,which really bugs me.

So I wanted to take them apart safely so I can add a few more coats of CA and really make sure I got it right.I remember reading here about how they can be hard to get apart.

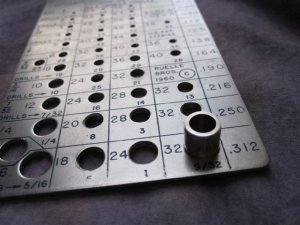

I made a tool by using a spare nib,and grinding off some of the small end just enough to fit a 5mm allen bolt in,then ground down a 5mm locknut into a cone shape,so there is room for it to thread onto an installed coupler.

Then with holding the pen in one hand vertically,I hook my small slide hammer onto the allen bolt,and just drop the slider.About the 3rd drop it falls out,allowing the exact HF transfer punch to pound out the clicker end.

I had to do six of them,and they all look perfectly OK,so I'm glad that I have a second chance on these.The blanks were so nice,and they cost a lot so I would have hated to cut them in half.I enjoy making these pens,but they have been just the biggest challenge for me to get them right!

I used my expensive Snap-on slide hammer,but HF sells a cheap knockoff for about $20.00 that probably would work just as well for this light-duty application,I would thnk.

I posted a few pics on the last page (6) of my photobucket in case anyone wanted to see.

click http://361.photobucket.com/albums/oo52/ossaguy

I just thought that since it worked so slick,seeing this might help someone else.

Take care,

Steve

I recently made a group of long click pens,and even after measuring with calipers I still ended up with a razor sharp edge you can feel at the nib/barrel transition.It really bugs me if I can feel it.I guess I was in a hurry making them,only to scrutinize them later at home.

One had a migrating clip too,which really bugs me.

So I wanted to take them apart safely so I can add a few more coats of CA and really make sure I got it right.I remember reading here about how they can be hard to get apart.

I made a tool by using a spare nib,and grinding off some of the small end just enough to fit a 5mm allen bolt in,then ground down a 5mm locknut into a cone shape,so there is room for it to thread onto an installed coupler.

Then with holding the pen in one hand vertically,I hook my small slide hammer onto the allen bolt,and just drop the slider.About the 3rd drop it falls out,allowing the exact HF transfer punch to pound out the clicker end.

I had to do six of them,and they all look perfectly OK,so I'm glad that I have a second chance on these.The blanks were so nice,and they cost a lot so I would have hated to cut them in half.I enjoy making these pens,but they have been just the biggest challenge for me to get them right!

I used my expensive Snap-on slide hammer,but HF sells a cheap knockoff for about $20.00 that probably would work just as well for this light-duty application,I would thnk.

I posted a few pics on the last page (6) of my photobucket in case anyone wanted to see.

click http://361.photobucket.com/albums/oo52/ossaguy

I just thought that since it worked so slick,seeing this might help someone else.

Take care,

Steve