DonHo

Member

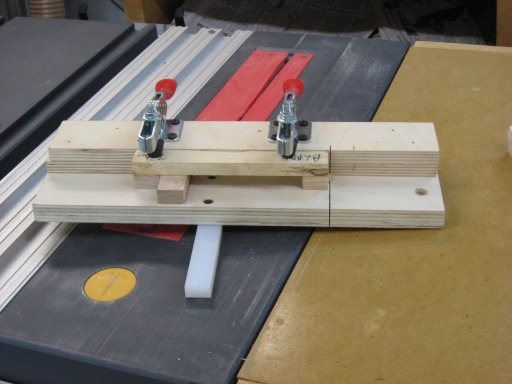

I want to give credit to sah6139 for the basic idea behind this jig. After reading his post about his tablesaw sled I adapted his idea to use with a bandsaw. The jig uses the pen tube to measure the cut on the blank and is adjusted so it cuts the blank 1/16" longer than the tube.

Thanks for looking

DonHo

Thanks for looking

DonHo