Hello John,

Thank you for posting the pictures and your detailed description of the failure. Here are my thoughts:

Sanding the pieces to give them more tooth is good. That is especially helpful with very smooth surfaces, like metal.

CA glue doesn't deal well with surface contaminants. Are the woods you were working with oily? If so, I would recommend using a solvent like acetone or denatured alcohol on them to remove the oil prior to gluing. Otherwise, you will have a very weak bond. Make sure that any solvent you use has completely dried before you apply the glue.

I don't recommend applying glue to both pieces. When bonding with cyanoacrylate, you want to use just as much as you need to fill the gap between the pieces. A thicker layer of CA glue will cure more slowly and result in a weaker joint. Just apply the glue to one part. I would suggest hitting the other part with a light mist of accelerator. If the materials are very dry you will have a hard time getting cyanoacrylate to cure at all without an activator.

CA glues cure with finger pressure. Are your rubber bands able to provide much clamping pressure? If so, they should work fine. You shouldn't need to apply pressure for more than 30 seconds or so, but it won't hurt to keep doing so.

Another reason that bonds fails is old glue. Glue that is past its shelf life cures more slowly or not at all. However, you said that it was a recent purchase at the time and that you used the rest of it for finishing successfully, so that doesn't sound like the problem.

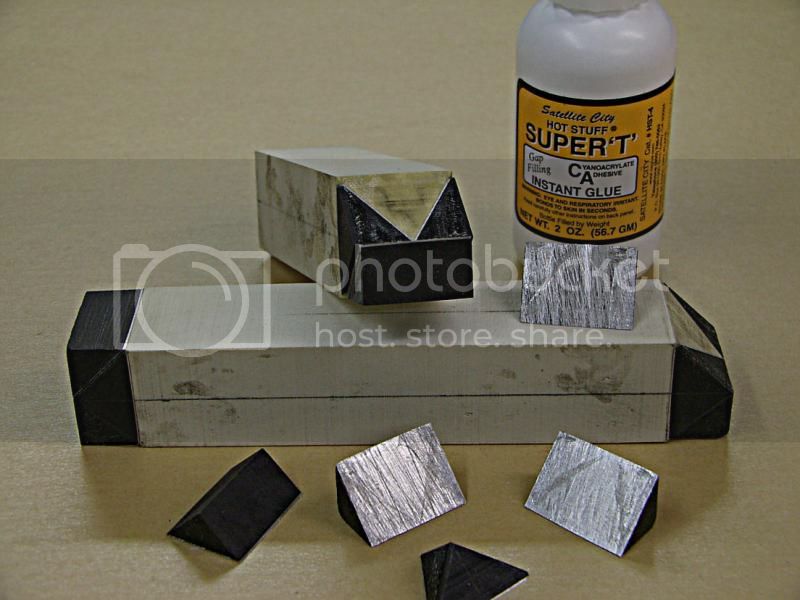

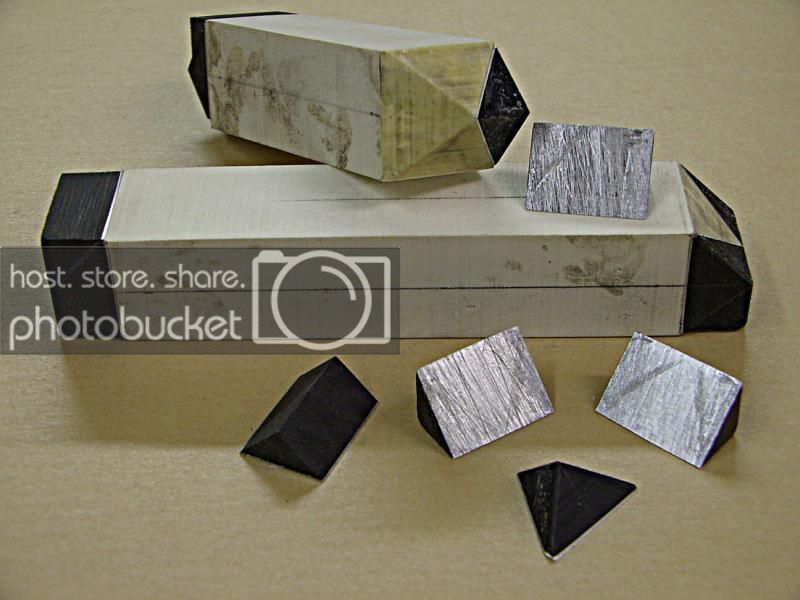

There's no reason you can't get a great bond between wood and aluminum. Here's a

short demonstration of bonding some aluminum to some scrap wood. You can see that the glue develops quite a bit of strength very quickly so that the two only separate when struck forcefully on a concrete floor, and the aluminum tears some of the wood off. The strength would be much greater after 24 hours as well. I think with just a few tweaks to your application, you would be very satisfied with Super T's bonding strength. If you'd like to PM me your information, I'd be happy to send you another bottle and some accelerator for you to try again.