sbwertz

Member

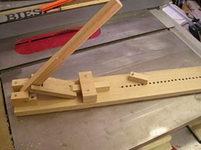

It was difficult for my blind students to use a standard lever operated pen press. I had made these wooden mandrels for turning peppermills, and by putting one in the head stock and tail stock they are able to assemble their own pens with only a little help, just by turning the tailstock wheel to press the parts together. It has a #2 morse taper on one end and a one inch tenon on the other that fits in a 1 inch hole on a peppermill blank.