GDIS46

Member

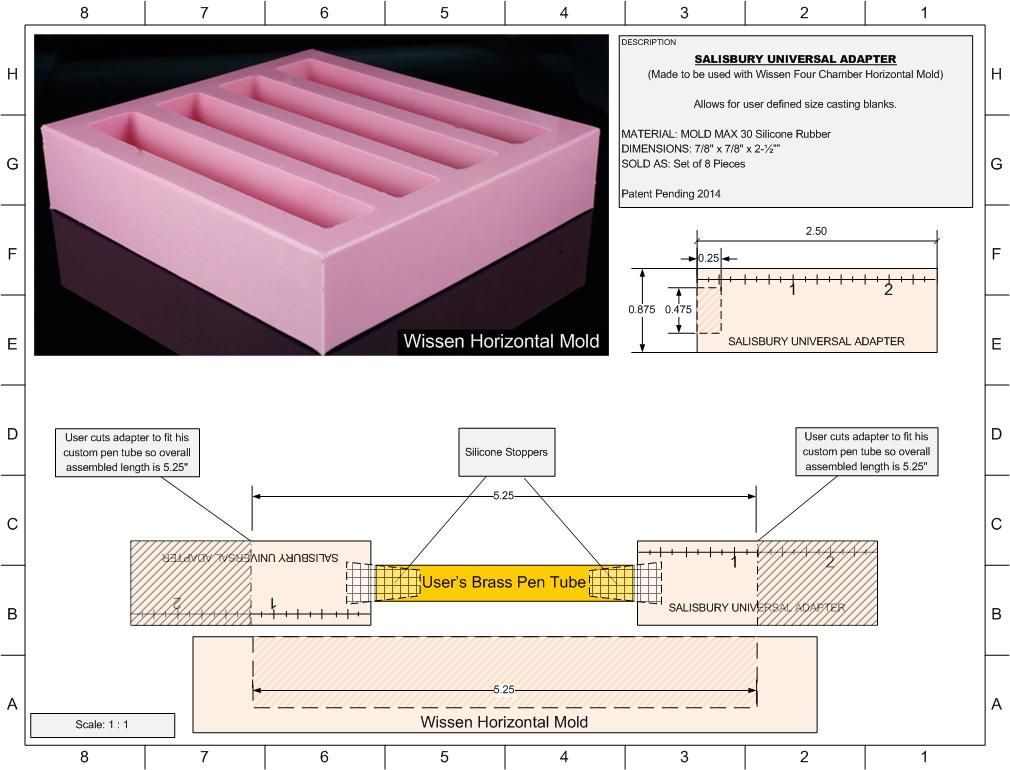

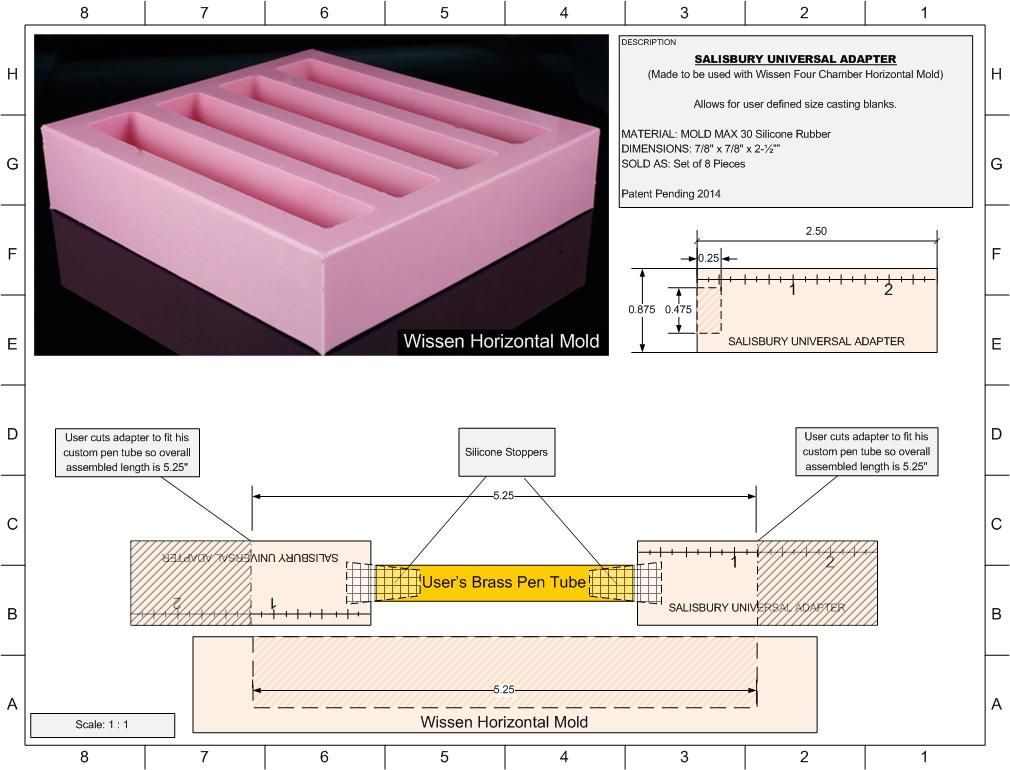

I like to cast my own blanks but sometimes there isn't a mold available for a particular pen kit that I want to use. For example: no one makes a mold for the Colt .45 caliber pen. So, being the resoursefull little turd I am, I developed an adapter for the Wissen Four Chamber Horizontal Mold.

I contacted Fred Wissen to pitch my idea for him to manufacture and market but he wasn't interested. So, I am here by releasing the idea into the public domain for anyone to make for themselves however, I am retaining the patent rights to it so you do not take my idea and make money off it without some compensation to me. Here it is, the Salisbury Universal Adapter.

Gary Salisbury

I contacted Fred Wissen to pitch my idea for him to manufacture and market but he wasn't interested. So, I am here by releasing the idea into the public domain for anyone to make for themselves however, I am retaining the patent rights to it so you do not take my idea and make money off it without some compensation to me. Here it is, the Salisbury Universal Adapter.

Gary Salisbury