kentonjm

Member

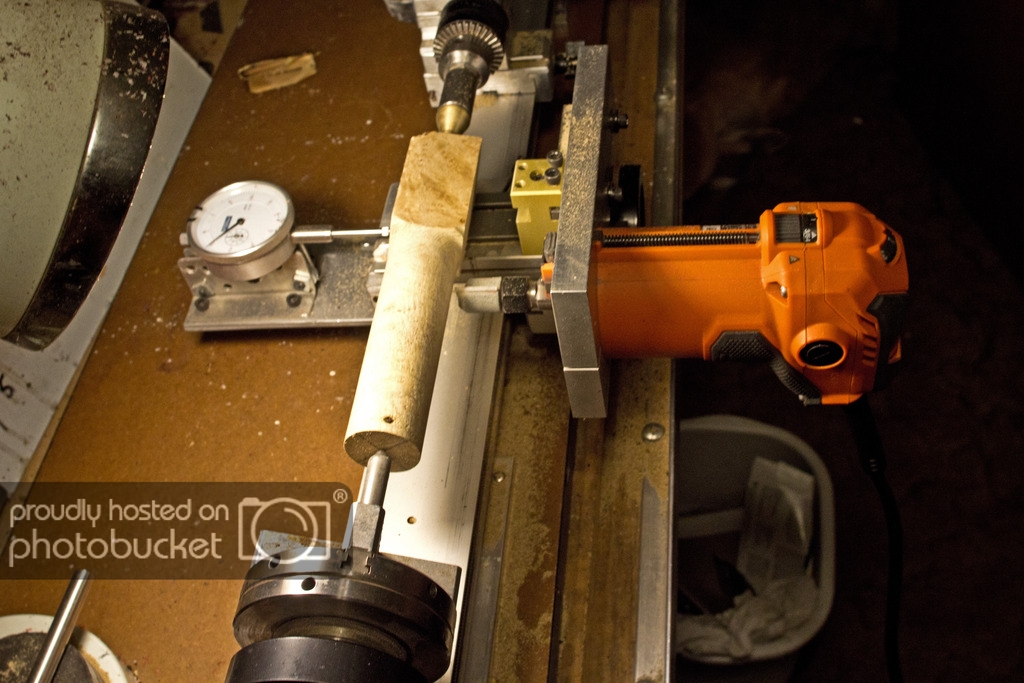

I have some blanks that I guess are spalted tamarind or pretty close to it. They are not particularly punky but they are softish. I have tried a few times to use them and each time I end up blowing out the ends as I get closer to final diameter.

The tubes were glued using thick CA which seems to have worked for everything else I have tried. Should I be trying epoxy or gorilla glue?

Undoubtedly my technique and patience could be improved and I have tried with both carbide tools and a skew both of which see to be fine until the blank gets thinner.

Not sure I am ready for a home stabilization setup or is that the real solution here?

I am sure this is partly the nature of the beast but what tips would you great folks have to help me actually be able to make a pen from one of these blanks. Thanks

The tubes were glued using thick CA which seems to have worked for everything else I have tried. Should I be trying epoxy or gorilla glue?

Undoubtedly my technique and patience could be improved and I have tried with both carbide tools and a skew both of which see to be fine until the blank gets thinner.

Not sure I am ready for a home stabilization setup or is that the real solution here?

I am sure this is partly the nature of the beast but what tips would you great folks have to help me actually be able to make a pen from one of these blanks. Thanks