Think of it as a dead stop instead of a "jig". Right now I am only cutting 1/8" strips, the width of my saw cut. Zero clearance plate is important, I have not made one yet though and my strips fall to the floor. I can not say how thin the cut can be to be safe. I personaly will not rip anything without a push stick on smaller flat stock.

/

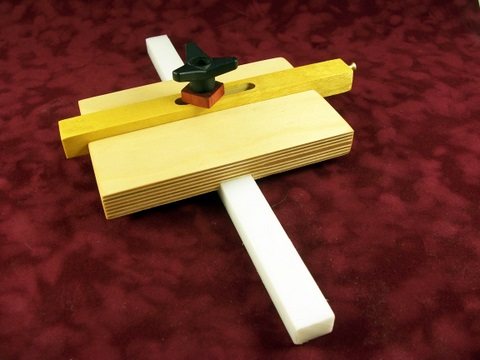

Usually the work you keep is between the blade and fence. In this case you set up the jig as a dead stop to the left of the blade and set your work on the left side of the fence. Set the distance between the brass screw on the left facing kerf on the blade to the thickness you want. Then move the jig towards you, away from the blade, bring the fence with the work piece on it to the left until it hits the brass screw head and lock the fence. Remove the jig and make the cut. Use the strips that come off the left side of the blade, the position that most times are scrap. The jig is used to keep succsesive cuts the same thickness by moveing the fence and work material to the dead stop after each cut.

/

I currently have some smaller pieces glued to a sacrificial piece of flatstock to make the cutting easier.