JamesC

Member

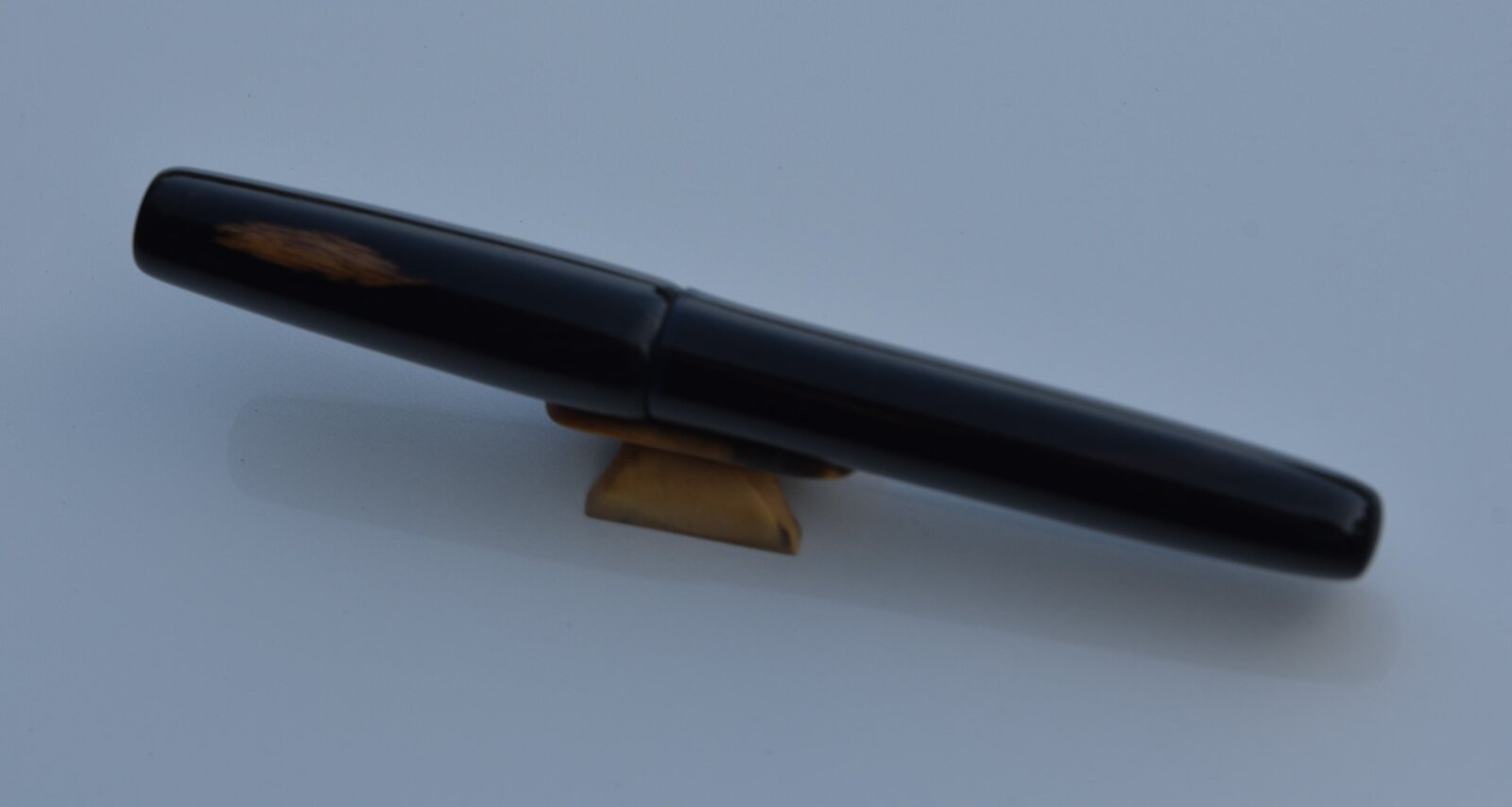

My most recent project was African Blackwood. The lumber is really pretty, very dark with a little brown. Hard to see unless you are in the sunshine. The cap has a little piece of the sapwood that I thought looked cool.

My problem is the cap when screwed on (M13 triple Start) will be a little off center unless the thread starts in the correct location. It's not much but really bothers me.

My process is to take the blank and turn them to 3/4" between centers. Live and dead centers are perfectly aligned at the headstock (wood Lathe). At this point I try and turn down close to the size I am after but the live center is now off center a little so the blank is not supported in the center. What is odd is the drill chuck mounted in the tailstock is dead on center.. I then center drill and then drill the appropriate size hole / holes for an insert.

I wonder if turning the blank between centers is creating a problem. All of my threading is done with a Niels sliding holder so I don't think its a threading issue. All of my issues seem to involve some don't think issue so I may be wrong.

Any suggestions, criticism is greatly appreciated.

Jim

Any suggestions?

Still pretty new at this so sorry if I missed a previous discussion regarding this issue.

Jim

My problem is the cap when screwed on (M13 triple Start) will be a little off center unless the thread starts in the correct location. It's not much but really bothers me.

My process is to take the blank and turn them to 3/4" between centers. Live and dead centers are perfectly aligned at the headstock (wood Lathe). At this point I try and turn down close to the size I am after but the live center is now off center a little so the blank is not supported in the center. What is odd is the drill chuck mounted in the tailstock is dead on center.. I then center drill and then drill the appropriate size hole / holes for an insert.

I wonder if turning the blank between centers is creating a problem. All of my threading is done with a Niels sliding holder so I don't think its a threading issue. All of my issues seem to involve some don't think issue so I may be wrong.

Any suggestions, criticism is greatly appreciated.

Jim

Any suggestions?

Still pretty new at this so sorry if I missed a previous discussion regarding this issue.

Jim