I've been researching a good bit on snakewood after having issues with it cracking myself. There are several things to consider when evaluating this material.

First is shrinkage:

With a T/R Ratio of 1.3, the radial surface is expected to shrink 4.7% and the tangential surface 6%. Total volumetric 10.7%. This means the radial surface (the flatsawn face grain where you can observe the vertical axis) will shrink 4.7% from green oven dry and the tangential surface (the end grain or quartersawn surface) 6% in the same amount of time. This ratio is in every wood and is why wood warps or cups even when properly stored. There is a 3rd axis called longitudinal shrinkage which runs lengthwise, but this is typically about 0.1%-0.2% and therefore not typically considered relevant.

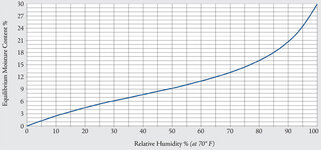

Ovendry is the driest state wood can reach, but is impossible to keep once it comes out of the oven. This is because the RH (relative humidity) of the environment around the wood presents it with moisture that is absorbed by the wood. Ovendry wood (wood at its driest - 0% MC), not kiln dried wood (wood that was dried in an oven) has a lower moisture content than the RH and will pull moisture from the air like a sponge. This causes it to swell and increase in volume. This shrinking and expanding due to RH is why old furniture cracks and why wood is said to be a "living" material.

Moisture content is calculated by weight of the moisture in the wood compared to the weight at an ovendry state. This means some green wood can have a moisture content over 100% when freshly cut. Wood will begin to lose moisture from the moment is cut and is considered "green" until it drops to around 30%. This is called the fiber saturation point (FSP). This is when the wood looses its "free water" which is the moisture in the pores and vessels of the wood. From 0.01% - 30% is considered to be "drying" and will find a natural equilibrium moisture content (EMC) where the moisture content will balance with the RH. This is where the wood gains or looses water trapped within the cell structure. If you keep your wood in an area with a relatively high RH, you will not see lower MC however if you keep your wood in storage where RH is controlled and kept lower than the natural RH of the environment the finished product will be in, you can expect swelling.

T/R ratios can range from about 1.0 to nearly 3.0. A T/R ratio of 1.0 means the wood will shrink in a perfectly uniform manner. This is purely theoretical however as the thicker the piece of wood, the slower the center will dry compared to the outer edges which are exposed more directly to the environment. On average, most woods have a 2.0 T/R. Snakewood is actually quite stable at 1.3. Radial shrinkage less than 2% is considered a very stable wood, snakewood has 4.7% and falls in the range between 3-5% found in most woods. The tangential range for most woods is 6-10%. Snakewood falls on the most stable range for average wood values.

*side note* an average of 2.0 means a flatsawn surface will shrink at twice the rate of a quartersawn surface and explains why quartersawn woods are considered more stable than flatsawn woods.

This means that the drying process for snakewood will be less likely to warp or mangle your specimen, but does not specify the rate at which it will shrink or swell after if finds EMC. To protect the wood a finish is applied. The best way to seal a wood and prevent absorption of moisture due to RH is to dip it in paraffin wax. This will prevent 95-99% of the moisture from affecting the wood. This is often why you find the paraffin wax on your exotic wood ends or over the whole piece; to prevent warping and cracking before the piece can be sold. Paraffin wax is not a good finish for a project, but 6 coats of shellac offers the second best level of protection (I don't have notes on CA finish, so I can't say for sure where that lies in the range) while paste wax, linseed oil and tung oil have very little protection against moisture.

*edit* Friction polish alone combines penetrating oils with (typically) a 1lb mix of shellac and is applied fairly thin. This offers little protection against moisture compared to 6 coats of 2lb shellac.

The second thing to consider is the nature of the wood. Snakewood is ranked as the 5th hardest wood with a Janka Hardness of 3,800lbf @ 12%MC. (This explains the blunting effect on your skew) It is ranked 4th in elasticity with a rating of 3,364,000 lbf/in^2 @12%MC. The grain in snakewood is very thin. The patterning is not to be confused with the actual wood grain. Snakewood, coming from coastal regions of northeast South America (from southern Mexico and Belize to Bolivia and Brazil)* exhibits similar grain characteristics to that of palm and other coastal trees where growth in width is slow. (Snakewood trees can be 65-80 ft tall, but only 6-12 inches in trunk diameter) This creates a very fine grain which is prone to cracking along the facegrane where the phloem and xylem of each growing season are tightly compressed and easy to separate.

*Figured snakewood is found in the lowlands occurring near rivers and creeks in rich brown soil.

In summary:

Snakewood is a fairly stable, very dense and often brittle specimen. It is very closely related to its less dense relative, bloodwood. It exhibits a very acceptable T/R ratio with an overall position low in the average range for wood shrinkage and although it can shrink up to 10.7% total volume from fresh cut, shrinkage is less an issue with snakewood than many other exotics we use. The primary consideration should be the brittle nature and density of the wood. Press fit components will exert an outward radial force on the face grain and encourage it to split between the phloem and xylem of the grain. A tight fit around a brass tube with a rigid glue will prevent movement of the inner wall as the outer surface is exposed to varying RH. As no finish is perfect for preventing RH from impacting the wood (especially considering the most susceptible part of the wood, the end grain, which is typically unsealed and faces the components of the pen) there will be mild expansion and contraction of the wood due to RH. The brittle and delicate nature of such thin pieces could be affected by RH even though it is a more stable wood than most.

Another fun fact about Snakewood, it is in the Mulberry family (fig family).

Don't take my word for it... here's some references:

Snakewood | The Wood Database - Lumber Identification (Hardwoods)

https://woodcollectors.org/pdf/wow-may-june-2015-2.pdf

parenchyma | plant tissue | Britannica.com

Tree Rings - What they Are and Why they Vary

Final thoughts... snakewood is hard to dry, so if you don't plan to sit on that piece for 10-20 years look more at your construction and techniques. The advice given already about loose fit components and selection of adhesive will give you the best possible chance at success. The nature of snakewood is a brittle and fragile one, prone to cracking no matter what you do.