timdaleiden

Member

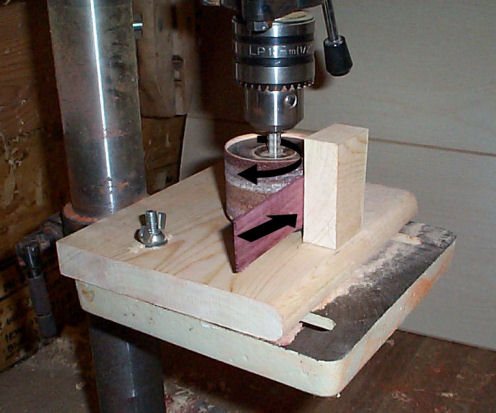

For perfect laminations, consistency is a must. Here is an inexpensive and easy to build jig to help you. I wish I had thought of it sooner.

Originally posted by Thumbs

<br />Thanks for sharing, Tim. It may not be the newest thing under the sun; but if we didn't know about it or think about it, what's the difference?[8D]

Originally posted by timdaleiden

You should have seen my old method of trying to get a consistent veneer. I basically sawed them with the band saw, and then took them over to the belt sander. It was sort of fun launching them across the shop, I guess, but really time consuming. []

What he said!!!!!!!!!!!!Eagle,

Why must you be so smug, arrogant and belittling in your posts. Why not just say thanks, Tim for that great idea, or say nothing. Oh, I know why, you've told us numerous times. you're Eagle! I may be the only on who has this thought, but I have it and just wanted to share. Do a good turn daily!

Don

Originally posted by timdaleiden

<br />Just for the record, I really wasn't offended by the other posters remarks. For those that feel comfortable with using their table saw and a sled for making veneers, I say "go right ahead".

For me, the table saw is used when I need it for large pieces. Quite frankly, mine is quite noisy, and it scares me a bit. I feel very comfortable with my band saw, and my scroll saw. I also feel very comfortable with this simple jig. It certainly is better than my old method. [:0]

I shared what I made because it saved me a lot of time and frustration, and I wanted to save other people from some of those same frustrations. It really does work nicely.