Im making fountain pen parts and thought I would share one of the steps im going through.

THis piece Im making is for the nib holder it is a Miester Nib #6. The black plastic piece has 7.4mm x .5mm threads. I took and tapped the brass piece to make sure I have the correct sized tap. The chrome piece in the back is from a Majestic Kit. it also uses a 7.4 x .5 but the lip at the front is larger in diameter

I could have threaded the inside threads using the lathe but the seat for the threads is deep inside the piece about 1/2 an inch and only 4mm long. I would have had to thread it blind. I mounted the silver piece in the lathe and drilled it with a "J" drill bit. then I bored out the rest of the dimensions to accept the lip of the black plastic piece.

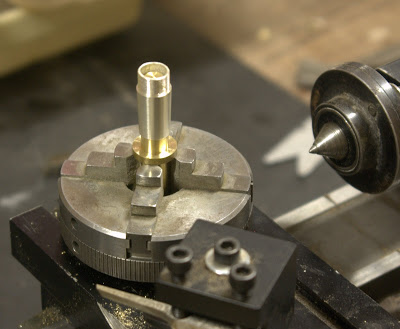

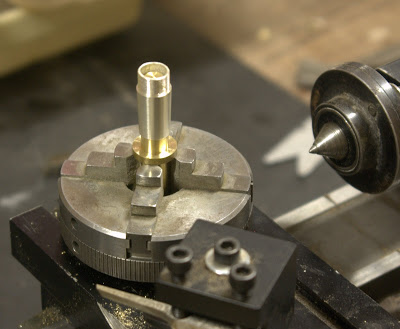

Picture 2 is of the silver piece mounted on a brass mandrel I made to hold the piece while I shaped the outside. The shape of the brass piece duplicates the black plastic nib piece. I have given it its final shape and it needs only final sanding and then the polishing stages. Because I need to thread this piece into the next piece Im making I also threaded the end that s up, 10mmx.5mm. I have a different lathe set up just for threading and I can leave the piece in the chuck as im working on it and move it from lathe to lathe to the mill if I need to. Because Silver is so soft I end up cutting the thread at about .001 at a time. The final 2 cuts are 1/2 that.

The next two pictures show the Nib assembled and with a Kit nib inserted for looks. You can see the threading on the back clearer in these pictures.

Mike

THis piece Im making is for the nib holder it is a Miester Nib #6. The black plastic piece has 7.4mm x .5mm threads. I took and tapped the brass piece to make sure I have the correct sized tap. The chrome piece in the back is from a Majestic Kit. it also uses a 7.4 x .5 but the lip at the front is larger in diameter

I could have threaded the inside threads using the lathe but the seat for the threads is deep inside the piece about 1/2 an inch and only 4mm long. I would have had to thread it blind. I mounted the silver piece in the lathe and drilled it with a "J" drill bit. then I bored out the rest of the dimensions to accept the lip of the black plastic piece.

Picture 2 is of the silver piece mounted on a brass mandrel I made to hold the piece while I shaped the outside. The shape of the brass piece duplicates the black plastic nib piece. I have given it its final shape and it needs only final sanding and then the polishing stages. Because I need to thread this piece into the next piece Im making I also threaded the end that s up, 10mmx.5mm. I have a different lathe set up just for threading and I can leave the piece in the chuck as im working on it and move it from lathe to lathe to the mill if I need to. Because Silver is so soft I end up cutting the thread at about .001 at a time. The final 2 cuts are 1/2 that.

The next two pictures show the Nib assembled and with a Kit nib inserted for looks. You can see the threading on the back clearer in these pictures.

Mike

Last edited: