jsolie

Member

I was on a roll today.

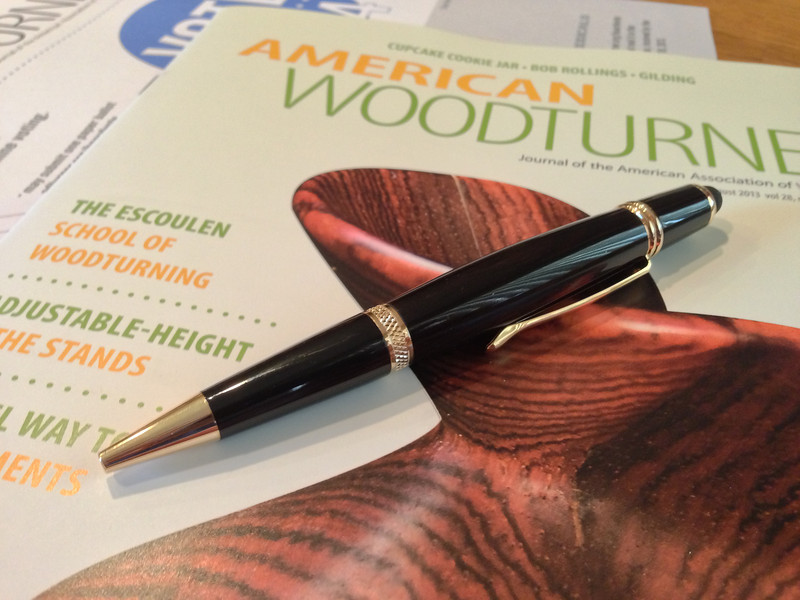

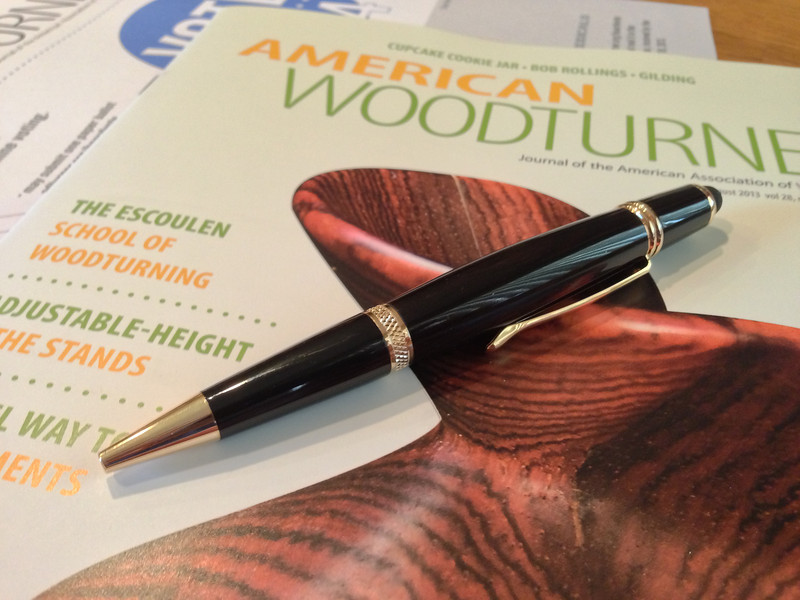

This is a Sierra Stylus pen made from Macassar ebony and given nearly 30 layers of thin CA, buffed out to 12,000 then several passes with Hut's ultra gloss. The finish on the wood is like glass.

The piece of Macassar ebony from which this piece was cut was nowhere even close to square, so drilling it was interesting. At first I thought the bit had wandered, but since the blank was so far from square, it probably didn't sit right in my drilling jig.

Since I don't have a Sierra-sized shaft for my end mill, I had to get inventive to trim the blank after gluing in the brass tube. I put a piece of 3/4" ply on one of my 3" faceplates, mounted that on the lathe, and grabbed a 3/8" bowl gouge. Out of this came a piece of wood to which I used double-sided tape to hold a piece of 100 grit sandpaper. My Jacob's chuck went into the tailstock with the right sized Harbor Freight transfer punch chucked up to hold the blank. I spun the lathe up to just about as fast as it would go, and trimmed the blank. Necessity truly is the mother of invention. It may not have been perfect, but I gave up trying to run a perfect shop years ago.

My oldest son (who's still recovering from his broken leg/sprained ankle) immediately sized it and was "testing" the stylus on his iPad. Riiiiight. I was able to get the pen away from him for some photos, but I suspect he's going to come looking for it.

Again, I didn't feel like setting up the big camera, so a cell phone shot will have to do.

(and can you tell what came in the mail today? :biggrin: )

This is a Sierra Stylus pen made from Macassar ebony and given nearly 30 layers of thin CA, buffed out to 12,000 then several passes with Hut's ultra gloss. The finish on the wood is like glass.

The piece of Macassar ebony from which this piece was cut was nowhere even close to square, so drilling it was interesting. At first I thought the bit had wandered, but since the blank was so far from square, it probably didn't sit right in my drilling jig.

Since I don't have a Sierra-sized shaft for my end mill, I had to get inventive to trim the blank after gluing in the brass tube. I put a piece of 3/4" ply on one of my 3" faceplates, mounted that on the lathe, and grabbed a 3/8" bowl gouge. Out of this came a piece of wood to which I used double-sided tape to hold a piece of 100 grit sandpaper. My Jacob's chuck went into the tailstock with the right sized Harbor Freight transfer punch chucked up to hold the blank. I spun the lathe up to just about as fast as it would go, and trimmed the blank. Necessity truly is the mother of invention. It may not have been perfect, but I gave up trying to run a perfect shop years ago.

My oldest son (who's still recovering from his broken leg/sprained ankle) immediately sized it and was "testing" the stylus on his iPad. Riiiiight. I was able to get the pen away from him for some photos, but I suspect he's going to come looking for it.

Again, I didn't feel like setting up the big camera, so a cell phone shot will have to do.

(and can you tell what came in the mail today? :biggrin: )