rherrell

Member

I decided to get in to knife making and after looking at all the options I decided it would be fun (and cheaper) to make my own.

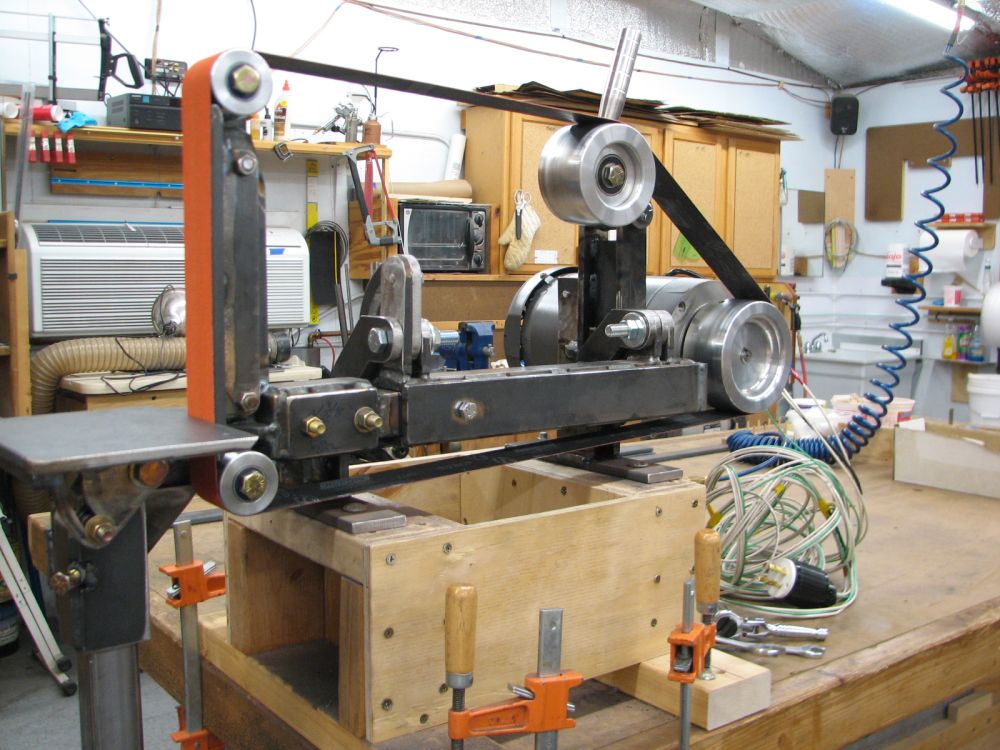

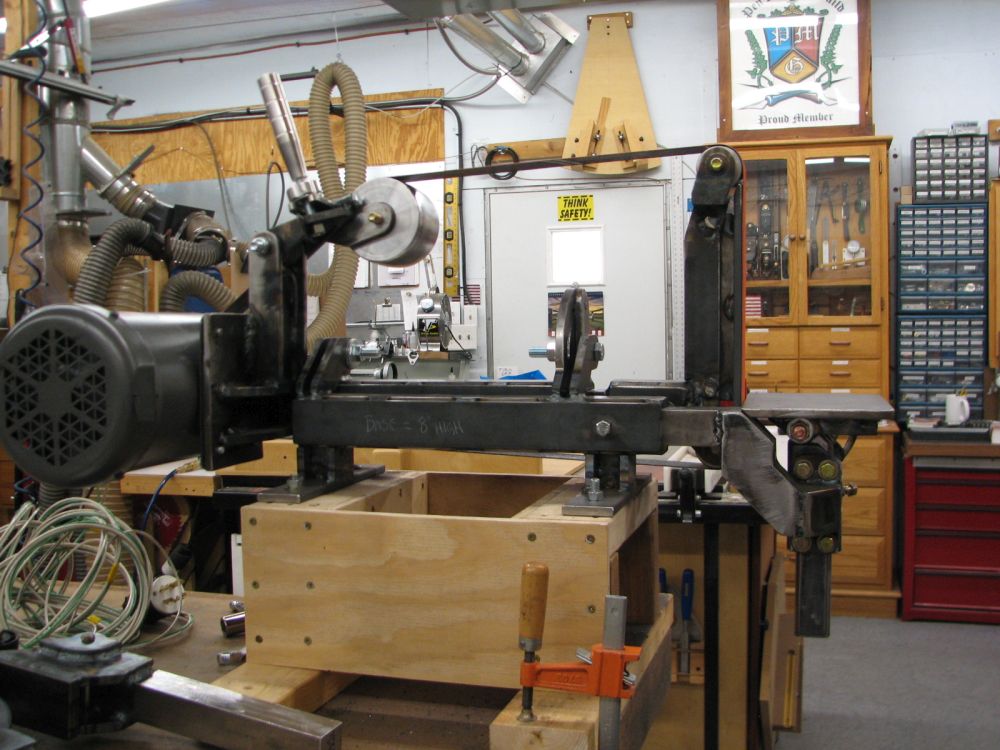

I didn't think about pics until I was almost done so I'm sorry but no "in progress" photos.

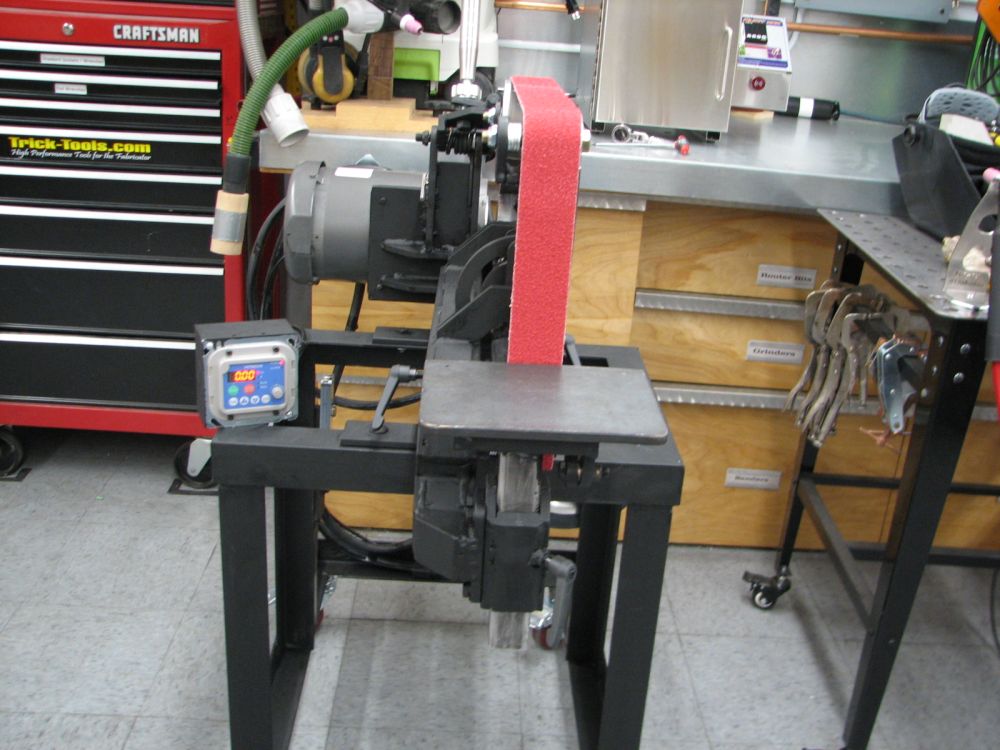

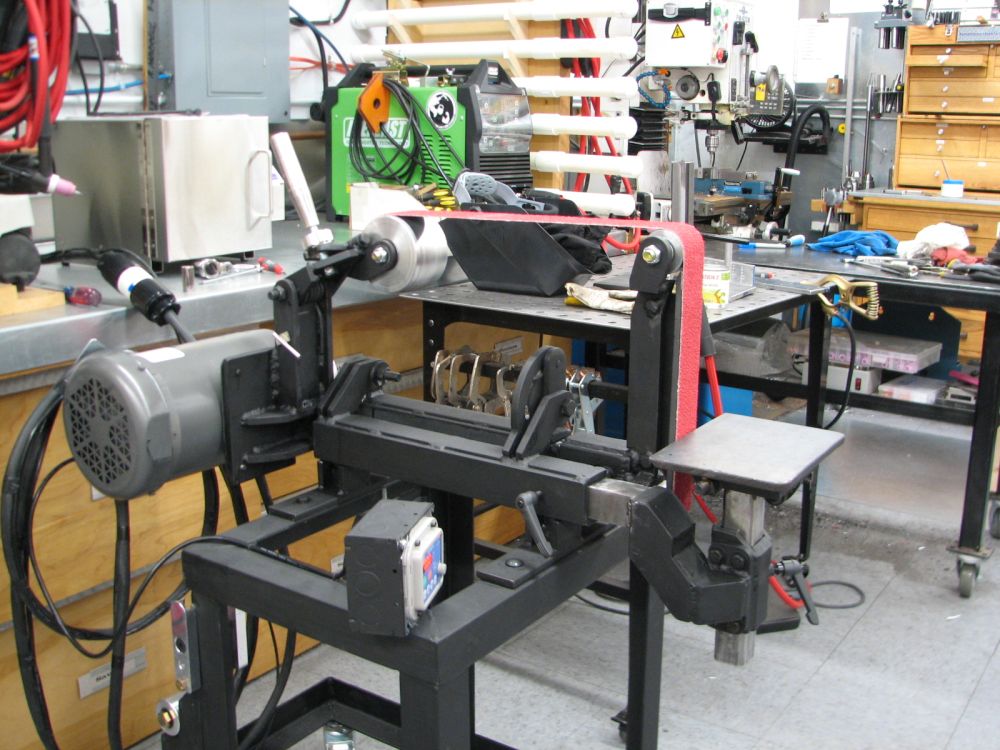

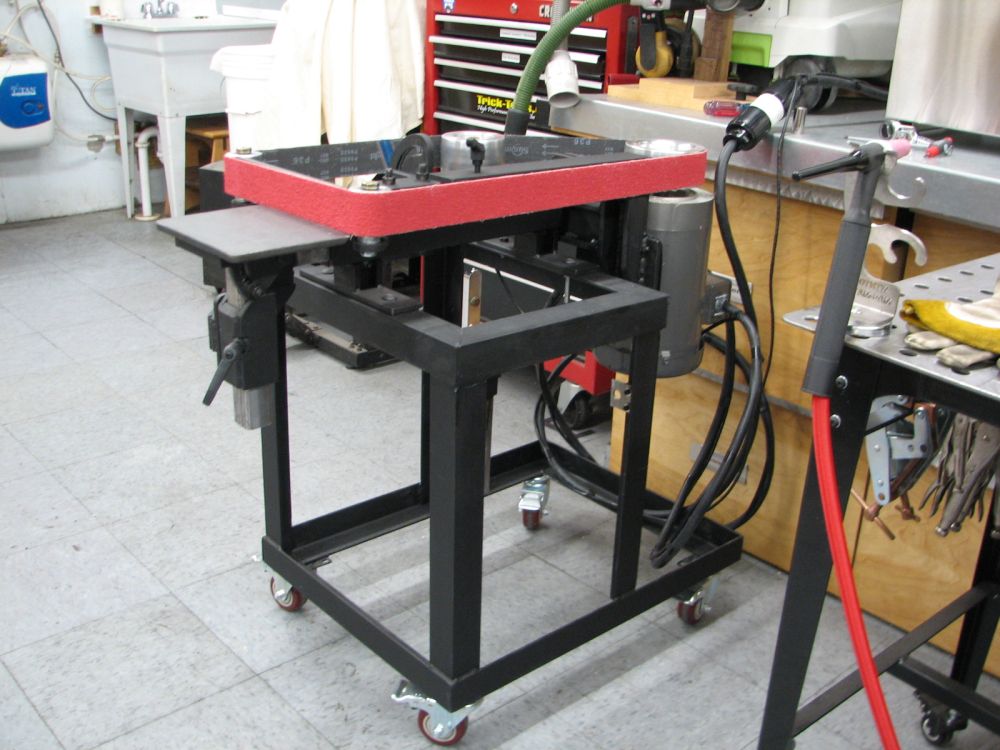

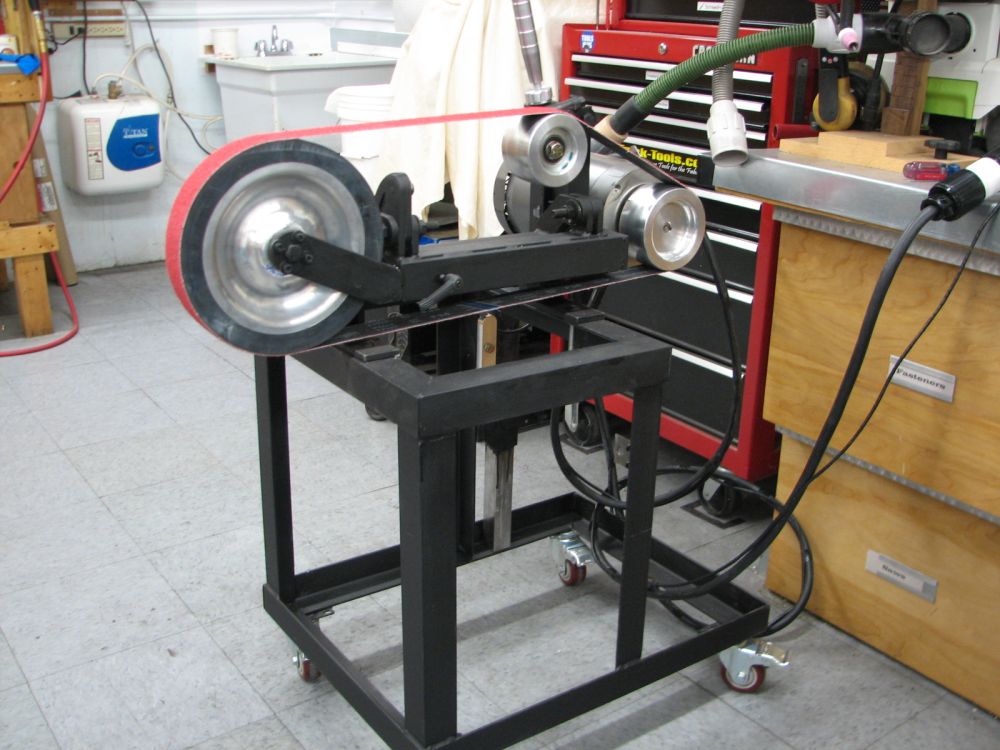

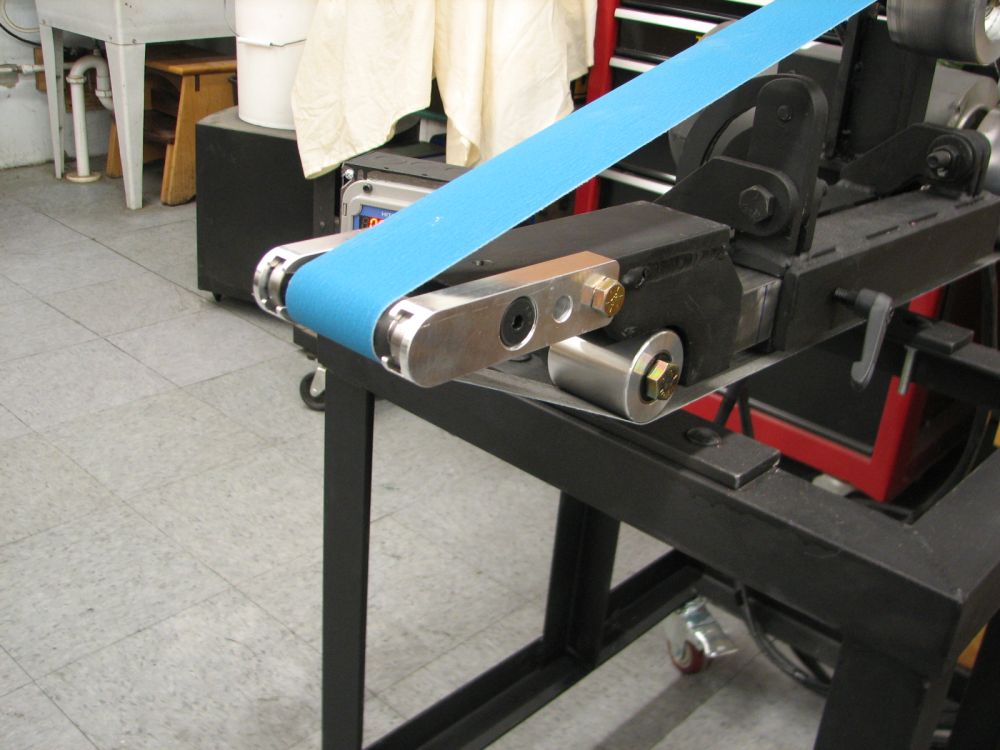

Those are the main parts before paint, here's the finished grinder...

I got the plans online from Jer's Woodshop, he also has a You Tube channel where you can see him build it. The plans are only $20 if you're interested.

I didn't think about pics until I was almost done so I'm sorry but no "in progress" photos.

Those are the main parts before paint, here's the finished grinder...

I got the plans online from Jer's Woodshop, he also has a You Tube channel where you can see him build it. The plans are only $20 if you're interested.