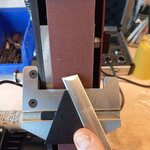

I made my first pens and I'm happy about them so far. Still al lot to learn but they are not bad at all. I will post some pics soon. I have a cheap set of diamond plates which go up to 320 grit and made a strop myself out of an old belt. I noticed I only use my 19mm/ 3/4 inch skew and some parting tools and I wanna keep it at that.

Now, I can buy a Tormek with a guiding piece but is seems a bit excessive for the 3 chisels I use so I thought a set of DMT diamond plates 320, 600,1200 should do it. Would that be enough or do I need something else in the long run? Otherwise it would be ashame to spend a 100 euros on the diamond plates and then again 400 for the Tormek in a year.

It's already turning into quite some money and I don't wanna overdo it. But what needs to ben done needs to be done.

I know there are a lot of topics about the subject but I wanna know can I manage with only the diamond plates?

Greetings Niels

Now, I can buy a Tormek with a guiding piece but is seems a bit excessive for the 3 chisels I use so I thought a set of DMT diamond plates 320, 600,1200 should do it. Would that be enough or do I need something else in the long run? Otherwise it would be ashame to spend a 100 euros on the diamond plates and then again 400 for the Tormek in a year.

It's already turning into quite some money and I don't wanna overdo it. But what needs to ben done needs to be done.

I know there are a lot of topics about the subject but I wanna know can I manage with only the diamond plates?

Greetings Niels