RetiredJake

Member

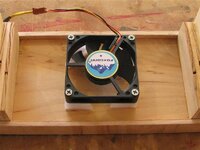

I watched Drstrangefart's shaker table and decided I could do something similar. Since I do not cast round blanks, I made mine a little different. Just big enough to handle one mold at a time.

The neighbor was trashing an old computer, so I grabbed the DVD drives and the CPU cooling fan. Got the first DVD motor out and realized that I needed a Double E to figure out how to control it. Looked at the cooling fan, it only had 3 wires, should be simple. Hooked up a 9 volt battery and figured out the wiring. Started cutting blades off the fan until it shook enough to make me happy. Made a small table and mounted the fan. Played with a bunch of different wall warts until I found one that ran at the best speed (most vibration). Turned out, a 4.5 volt unit performed best. During my test run, the mold wanted to walk right off the side of the table, so I added the short border to keep it in place. Set it on some rubber matting and it works like a champ.

Comments welcome. Thanks Drstrangefart for the idea.

Jake

The neighbor was trashing an old computer, so I grabbed the DVD drives and the CPU cooling fan. Got the first DVD motor out and realized that I needed a Double E to figure out how to control it. Looked at the cooling fan, it only had 3 wires, should be simple. Hooked up a 9 volt battery and figured out the wiring. Started cutting blades off the fan until it shook enough to make me happy. Made a small table and mounted the fan. Played with a bunch of different wall warts until I found one that ran at the best speed (most vibration). Turned out, a 4.5 volt unit performed best. During my test run, the mold wanted to walk right off the side of the table, so I added the short border to keep it in place. Set it on some rubber matting and it works like a champ.

Comments welcome. Thanks Drstrangefart for the idea.

Jake