PatrickR

Member

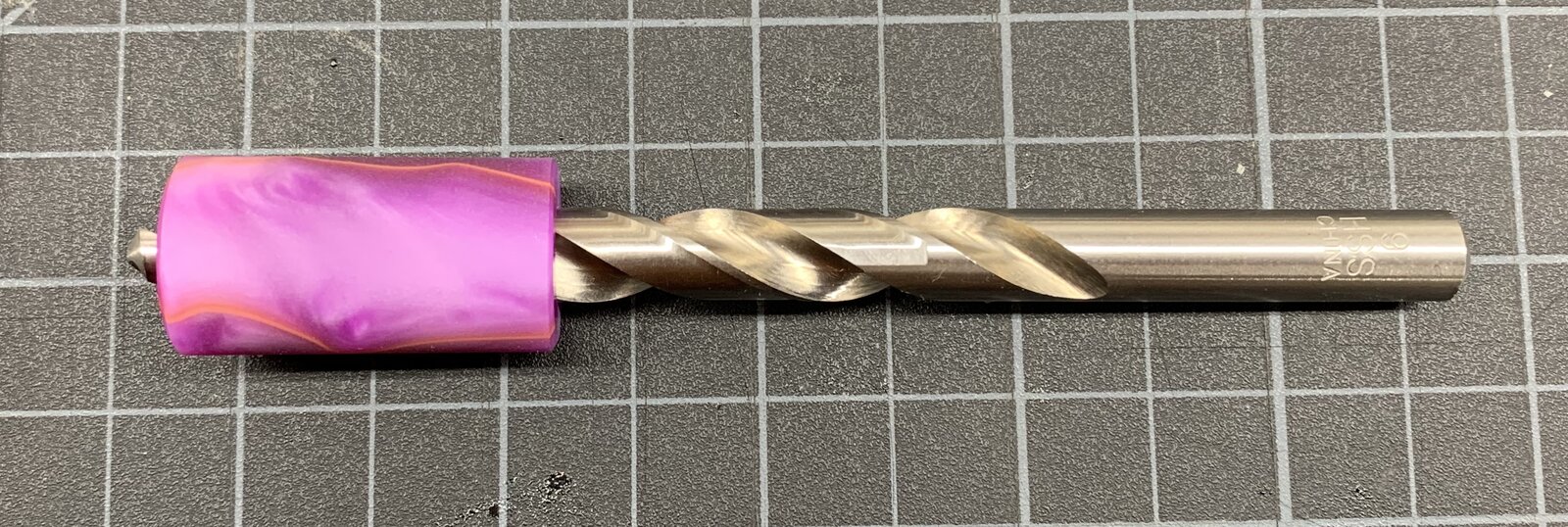

@rherrell made me two step bits. One each for Bock #6 and #5. I have not tried the #5 yet but will soon and report back here.

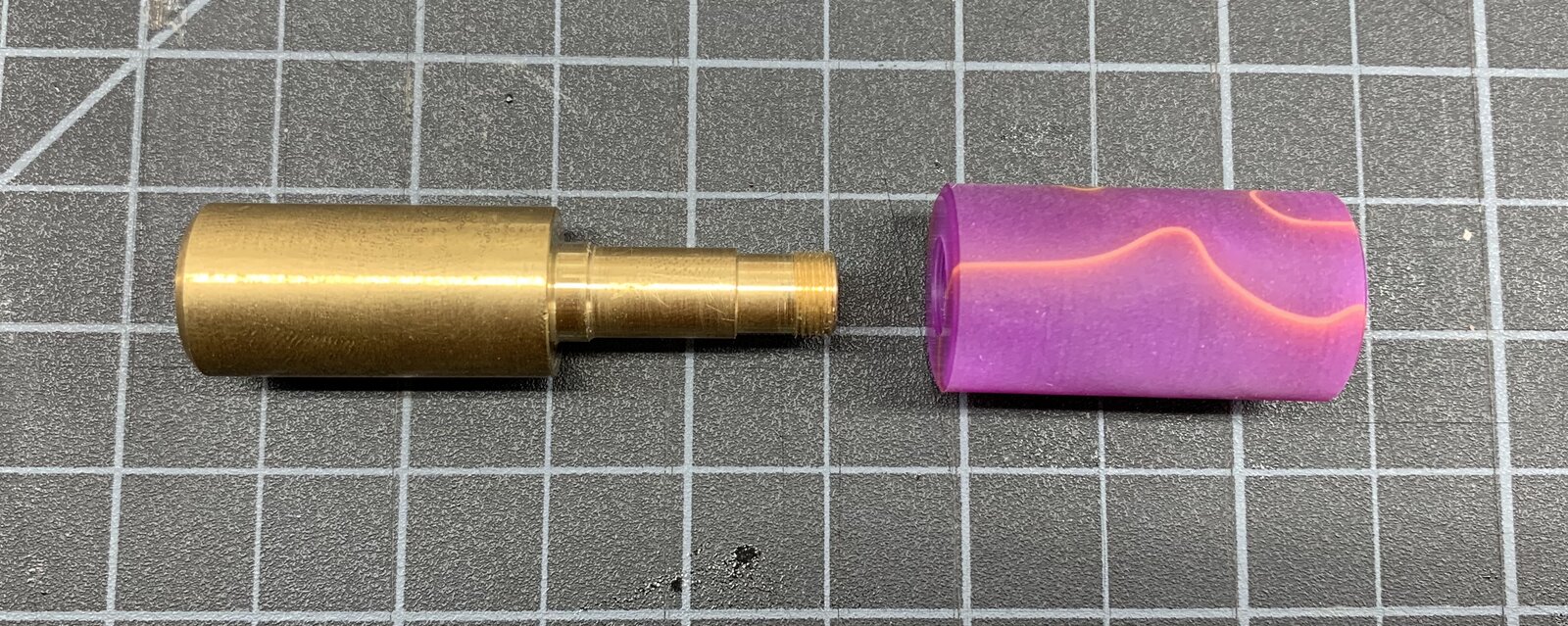

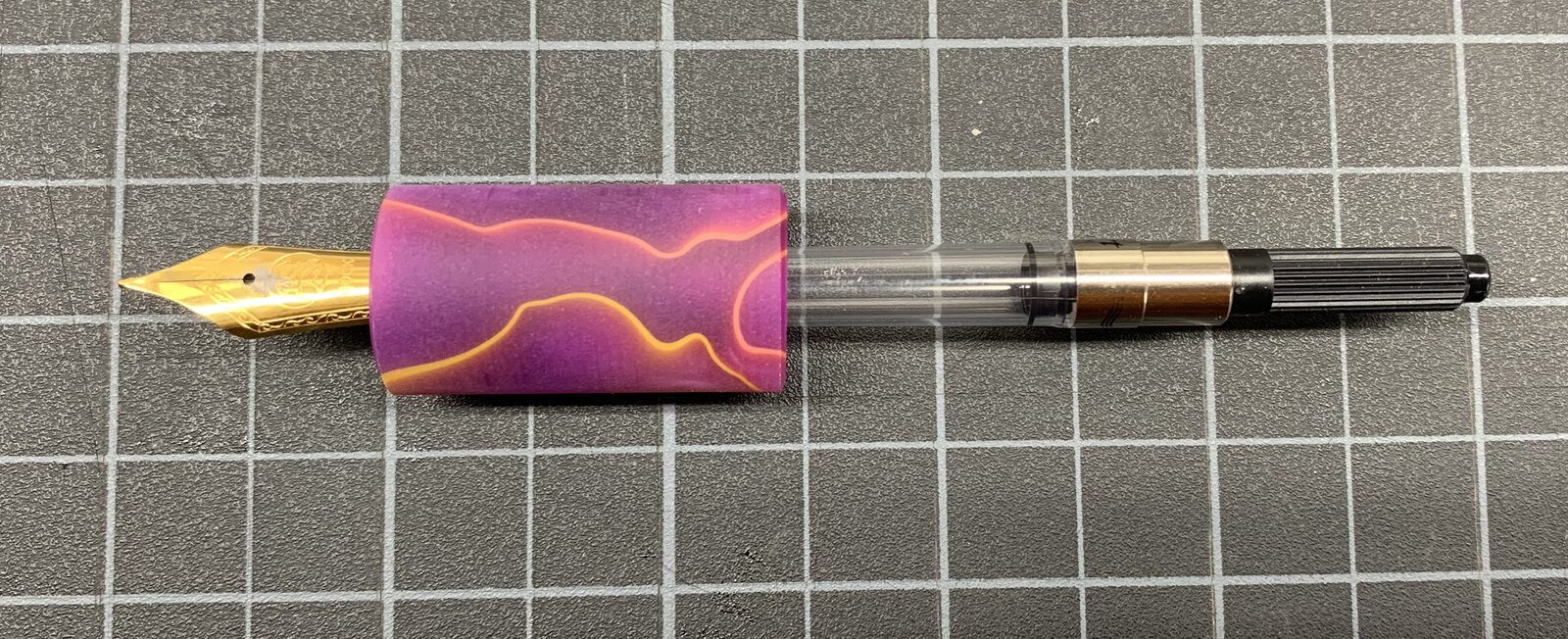

This worked perfectly. One hole to drill with no measuring, for what used to take 3 different bits with one having a fairly tight tolerance for depth. Simply drill through the blank and stop when the largest portion of the bit goes deep enough to burry the housing flange. Then run the tap all the way through. Sooooo much faster. Thanks to Rick for the usual high quality work and attention to detail! Shown here on a Beaufort mandrel.

This worked perfectly. One hole to drill with no measuring, for what used to take 3 different bits with one having a fairly tight tolerance for depth. Simply drill through the blank and stop when the largest portion of the bit goes deep enough to burry the housing flange. Then run the tap all the way through. Sooooo much faster. Thanks to Rick for the usual high quality work and attention to detail! Shown here on a Beaufort mandrel.