A friend sent me a piece of Australian Lacewood which I cut into blanks that are approx 3/4X1/2". When I turned the two I've glued u), when I got down to the finish turning phase, the wood breaks off the tube(on the ends). Any suggestions as to why and also what I can do to stop this? Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question on lacewwood

- Thread starter mikeinco

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

ChrisD123

Member

lacewood is very brittle especially around the lacey part, using more super glue at the ends when you glue the tube in may help or sand it down when ur within 1/16 of finished size

ChrisD123

Member

what glue are you using currently, try 1/8 then. what tools do you use for turning?

triw51

Member

I found very LIGHT cuts helps with brittle wood also using thin CA on the blank after a few cuts helps strenghten the wood.

mmayo

Member

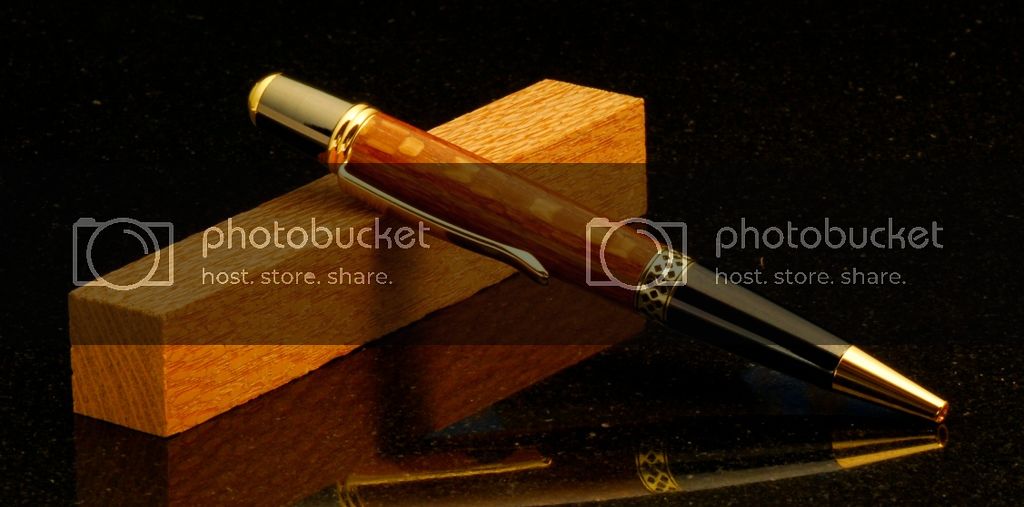

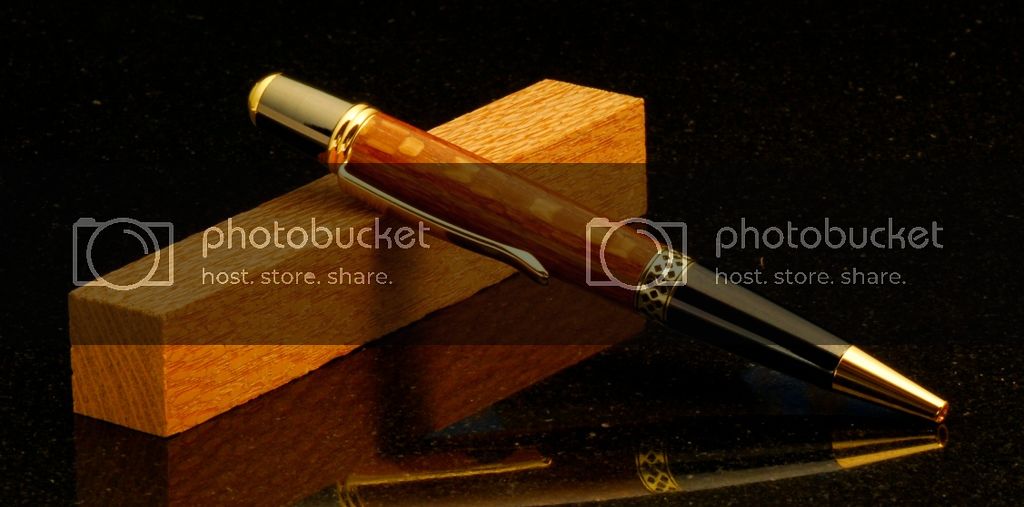

I had this problem and it was due to cutting the blanks 90 degrees off of the grain direction. You may have cut it correctly, but once I bought a new piece and cut it correctly it turned nicely. I fully agree that the large figured portions can be nasty if you aggressively turn like you can with other woods. CA nicely fills in the grain and makes the figure and color pop.

Last edited:

Very nice work there Mark. I've been using a thick CA to glue in tubes and cut the plank with the grain. I don't use a CA finish on pens, don't know how and kinda prefer the natural feel of the wood. I may try using some CA coats when I turn this wood, but am not sure if I could then use my regular finish. Thanks for the replies.

vtgaryw

Member

Funny, but I like Lacewood, and have never had a problem turning it. I've always thought it turned very nicely.

Gary

Gary

KenV

Member

May I suggest that if the wood breaks off the tube, there is a glue problem.

mark james

IAP Collection, Curator

A minor suggestion. After drilling your holes, dribble some thin CA into the hole to stabilize the INSIDE of the blank (the 1 mm that will be there after turning). Let set, then redrill and proceed to glue and continue with all above suggestions.

This originated from some Aussie Mates!

This originated from some Aussie Mates!

vtgaryw

Member

You know, when you hire cheap help you get what you pay for...

Ken, I was kinda thinking that might be the problem, my wife has been trying to help out by glueing up the blanks for me, so maybe I'll have to check her work.LOL

79spitfire

Member

When I've done lacewood, I've used 5 minute epoxy. I've also had good luck with Gorilla glue, but I let them sit overnight before turning.

When I run into that and some woods are like that for me the problem usually occurs at about 1/8th inch from finish. I just stop cutting with a tool sooner and use sandpaper. I'll start with 80 grit rather than the normal 150. It might at times be gluing but I use epoxy and rough up the tube and the glue does get well spread.