PenHog

Member

Hi,

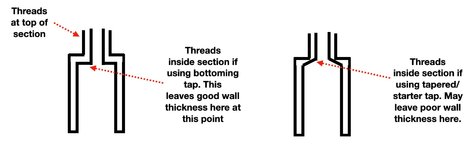

I was just wondering whether anyone knows where to purchase a bottoming tap for Jowo #6 nibs. I haven't seen this for sale, and so I wonder if it exists at all?

Thanks,

Max

I was just wondering whether anyone knows where to purchase a bottoming tap for Jowo #6 nibs. I haven't seen this for sale, and so I wonder if it exists at all?

Thanks,

Max