jbmauser

Member

I did not know where to drop this thread but since the folks here don't just build from kits I figured someone here may be thinking outside the box and toss me an idea.

I have half a dozen Polaris Pens that the kit parts are out of spec.

I am going to make these work but I wanted to ask if others have had a similar problem and found a fix. I have written to the seller in Australia asking for a remedy but I have one pen that needs to go now. And I may not get replacements.

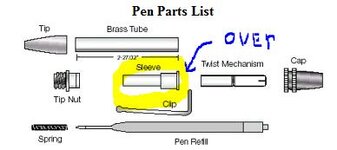

The problem is that the brass section of the transmission is a few thou smaller than the upper sleeve it is to be pressed into. I can wrap a single sheet of paper around it and it shims it up fairly well. My planned fix is to cut a paper shim, soak it in CA and then slip it in without fouling the transmission. If I use the minimum of CA it should work. Otherwise I will have an attractive brick to try and knock apart.

Anyone have and fixes. If the space were larger it might actually be easier. I could drill our a sleeve and then turn it down with my metal lathe but it would have to be mounted on the transmission which would not take the chuck nor the torque.

Ideas?

Thanks, JB

I have half a dozen Polaris Pens that the kit parts are out of spec.

I am going to make these work but I wanted to ask if others have had a similar problem and found a fix. I have written to the seller in Australia asking for a remedy but I have one pen that needs to go now. And I may not get replacements.

The problem is that the brass section of the transmission is a few thou smaller than the upper sleeve it is to be pressed into. I can wrap a single sheet of paper around it and it shims it up fairly well. My planned fix is to cut a paper shim, soak it in CA and then slip it in without fouling the transmission. If I use the minimum of CA it should work. Otherwise I will have an attractive brick to try and knock apart.

Anyone have and fixes. If the space were larger it might actually be easier. I could drill our a sleeve and then turn it down with my metal lathe but it would have to be mounted on the transmission which would not take the chuck nor the torque.

Ideas?

Thanks, JB

Last edited: