Larryreitz

Member

I have my new Neje 1500 up and running and would like to thank all those whose generous help got me around a couple of obstacles.

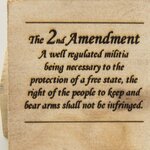

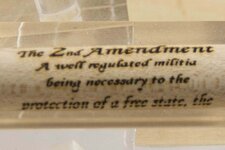

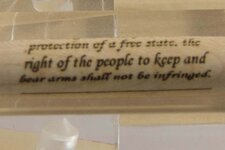

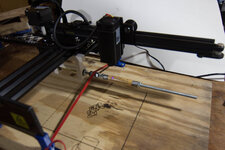

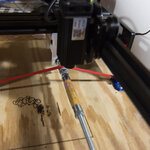

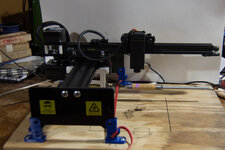

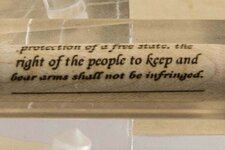

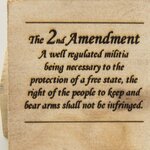

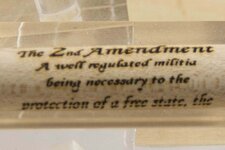

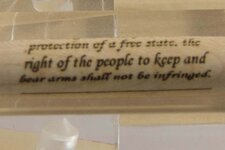

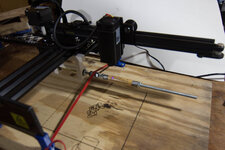

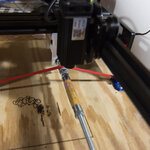

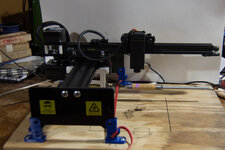

Now I would like to enlist some more help this time for engraving pen blanks with the rotary jig from T. Shadow. I have been trying to burn the 2nd Amendment as show in the first picture. It burns fine on flat stock, again pic #1. When burning a blank on the rotary jig not so much. The subsequent picture illustrate the problem. Some lines burn correctly and some burn thinner and smaller than they should. The picture was made in Photoshop and imported to the Neje software as a jpeg file. It is as if the font is changed, when it has not. Also the flat stock burn is the correct size. When the same file is burned on the pen blank it should go nearly completely around the circumference. Coverage varies from burn to burn but usually covers only half the circumference. The problem is illustrated on subsequent pictures. A few pictures of the set up are also include. Please pardon my messy desk. One thing of note (I don't know how important it is) is the laser beam hits the pen blank at about 11:00 rather than 12:00. Any suggestions would be greatly appreciated.

Larry

Now I would like to enlist some more help this time for engraving pen blanks with the rotary jig from T. Shadow. I have been trying to burn the 2nd Amendment as show in the first picture. It burns fine on flat stock, again pic #1. When burning a blank on the rotary jig not so much. The subsequent picture illustrate the problem. Some lines burn correctly and some burn thinner and smaller than they should. The picture was made in Photoshop and imported to the Neje software as a jpeg file. It is as if the font is changed, when it has not. Also the flat stock burn is the correct size. When the same file is burned on the pen blank it should go nearly completely around the circumference. Coverage varies from burn to burn but usually covers only half the circumference. The problem is illustrated on subsequent pictures. A few pictures of the set up are also include. Please pardon my messy desk. One thing of note (I don't know how important it is) is the laser beam hits the pen blank at about 11:00 rather than 12:00. Any suggestions would be greatly appreciated.

Larry