genopsdir

Member

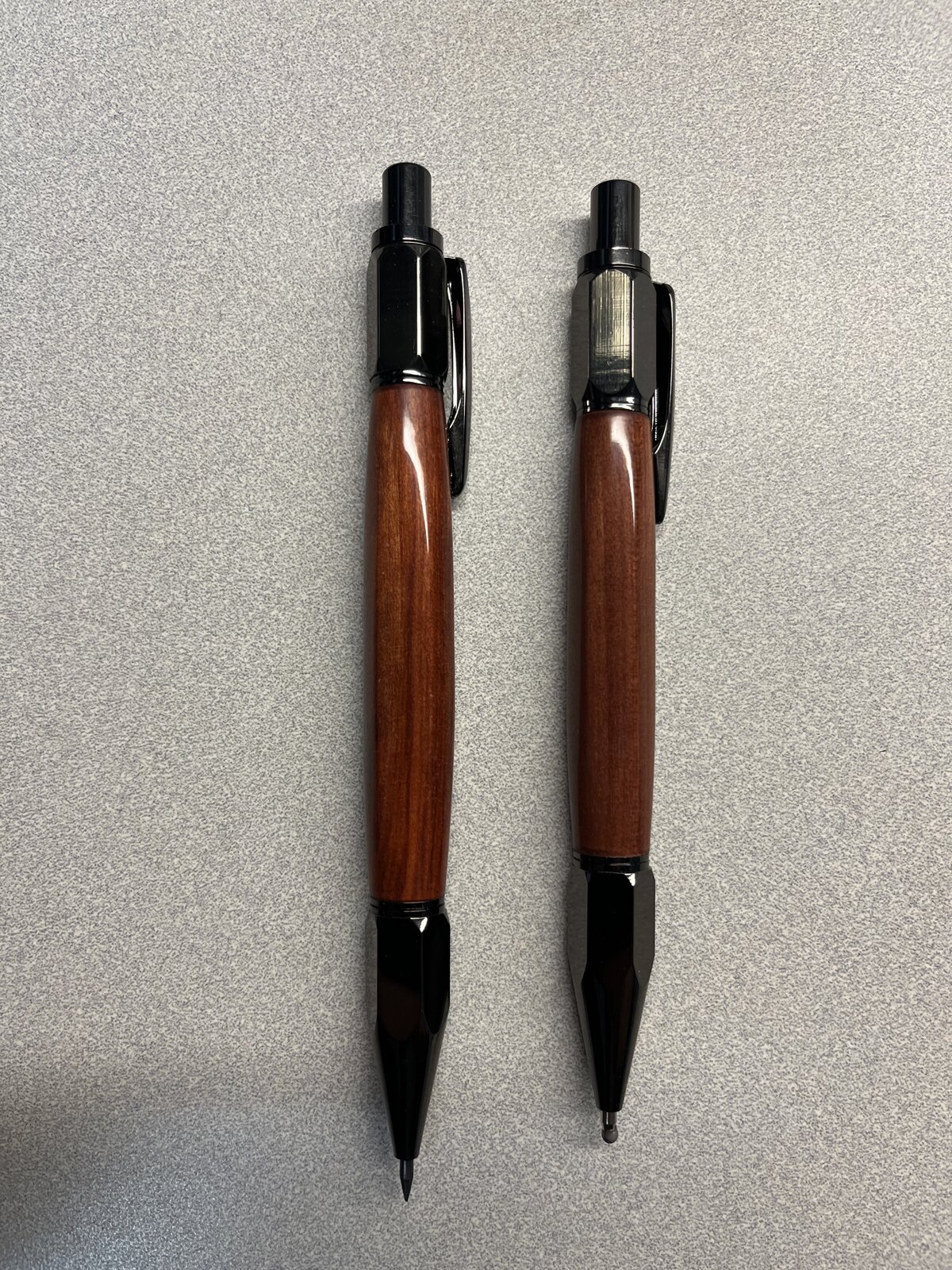

Figured out two methods for preparing hexagonal pen blanks and made a video to share.

Preparing Hexagonal Pen Blanks

Preparing Hexagonal Pen Blanks

Thank you!Thank you for sharing these ideas. the video is well done.

I like this idea and may have to incorporate it when making finials.Anther way is to build a faceting jig. I basically followed this idea. https://aussielapidaryforum.com/forum/index.php?topic=5569.0

I made a mandrel similar to the OP's system instead if the dopple glue stick I also added a mickey mouse indexing wheel and stop point so it would only allow so much to be sanded off.

Now I have to find it so I can add some nylon lock nuts.

I posted a YouTube video and Instructable Guide on how to make my jig now.Very clever methods to attain hexagon results. Thank you for sharing the video and the pictures. I have your site bookmarked. for future viewings, and reference Excellent workmanship. Very creative.

There are truely many jigs on the net and videos that show them that can be made for the lathe to use the router with. The one you are talking about is not offered from PSI any more and the down side to it was its footprint was too large . Especially when using pen blanks. The clamps on the lathe bed do not allow the tailstock to sinch up enough to hold the blank. Now a smaller version can easily be made using the same ideas and borrowing the table idea is also easy to adapt. The principle you mention about swirl marks is true and is always evident when we use turning tools also. When you lay a carbide tool or a skew on its side and use as a scraper you get a smooth edge on the blank but with alot more swirling and thus more sanding is needed. But if you put it up on its intended edge you get an even smoother cut and far less sanding because you now are using a micro part of that cutting blade. Same with a router bit if used at a 45 degree angle to the facets. So many designs can be added to a simple pen blank or decorative cap but takes a jig to repeatable make such cuts and have a indexing feature of some sort is very much needed.Well done!

My experience of faceting pen barrels is using a "fluting jig"from PennState, which comes with a table that clamps to the lathe ways, and has a fence the router jig runs along.

I found that "end milling" with the flat end of the router bit left a lot of swirl marks, and clean up took a long time (I had to start sanding at a coarser grit than I normally would). When I raised the router bit and pushed the whole thing over the workpiece, so it cut using the sides of the router bit, I got a much cleaner result and there was a lot less sanding required.

As they say - your results may vary.

I posted a YouTube video and Instructable Guide on how to make my jig now.Very clever methods to attain hexagon results. Thank you for sharing the video and the pictures. I have your site bookmarked. for future viewings, and reference Excellent workmanship. Very creative.

Thank you for sharing these ideas. the video is well done.

I posted a new video and Instructable on how I made the jig now. Hope this works well for you!I like this idea and may have to incorporate it when making finials.

Good to see others using the router to do some special things. I had shown my jig many years ago and use it all the time. In fact I have a pen in the works that needs to use this. Many ways to get to the finish line. Thanks for the video.

All good. It's about sharing the idea. I knew I was probably not the first to have this idea and I did use what I learned from others as well.There are truely many jigs on the net and videos that show them that can be made for the lathe to use the router with. The one you are talking about is not offered from PSI any more and the down side to it was its footprint was too large . Especially when using pen blanks. The clamps on the lathe bed do not allow the tailstock to sinch up enough to hold the blank. Now a smaller version can easily be made using the same ideas and borrowing the table idea is also easy to adapt. The principle you mention about swirl marks is true and is always evident when we use turning tools also. When you lay a carbide tool or a skew on its side and use as a scraper you get a smooth edge on the blank but with alot more swirling and thus more sanding is needed. But if you put it up on its intended edge you get an even smoother cut and far less sanding because you now are using a micro part of that cutting blade. Same with a router bit if used at a 45 degree angle to the facets. So many designs can be added to a simple pen blank or decorative cap but takes a jig to repeatable make such cuts and have a indexing feature of some sort is very much needed.

As I mentioned I made my own version of a router lathe jig that I have used many times and really need to expand on its use some myself. Someday I may even make a version#2 with added features that I have seen done over the years. Just way too much on the plate these days but here is my version and thread that was talked about. Sorry I did not and still do not have a method to make videos but if any questions I can answer. Not trying to steal or step on the OP thread and his version, just add some insight which seems like the thread is heading.

https://www.penturners.org/threads/my-jig.104253/