budnder

Member

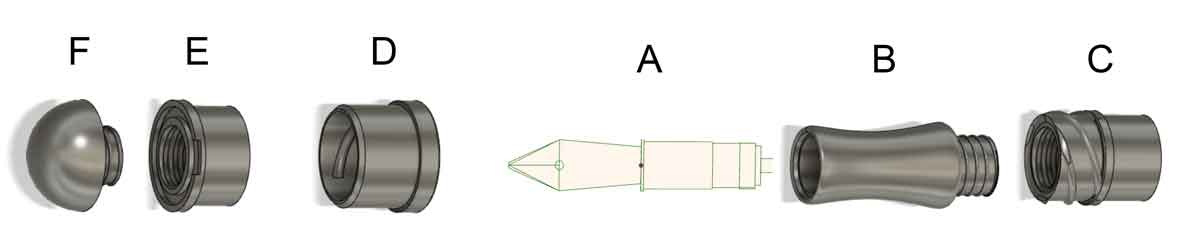

I've been working on designing my own fountain pen "kit", and am wondering if there are any common terms for some of these parts... I have 5 kit components, which I think is relatively common for a clos:

A) the nib (e.g. Bock #6)

B) the section - the part the nib screws into that you actually hold when you write. It's typically threaded on it's end to mate with c) below.

C) the "section receiver"? - the part the section screws into that has external threads for the cap to screw on to. Typically this is glued/pressed into the body of a pen.

D) the "cap end"? - typically glued/pressed onto the end of the cap, this screws onto c) above when you cap the pen.

E) the "finial receiver"? - typically glued/pressed onto the finial end of the cap and typically the pen clip will sit onto this in a notch designed to restrict the pen clip from spinning

F) the "finial" - typically screwed into e) above to secure the clip and provide a nice visual to the top of the pen

It's C, D, and E that I feel like, I just made up the terms for... what do you call those bits?

A) the nib (e.g. Bock #6)

B) the section - the part the nib screws into that you actually hold when you write. It's typically threaded on it's end to mate with c) below.

C) the "section receiver"? - the part the section screws into that has external threads for the cap to screw on to. Typically this is glued/pressed into the body of a pen.

D) the "cap end"? - typically glued/pressed onto the end of the cap, this screws onto c) above when you cap the pen.

E) the "finial receiver"? - typically glued/pressed onto the finial end of the cap and typically the pen clip will sit onto this in a notch designed to restrict the pen clip from spinning

F) the "finial" - typically screwed into e) above to secure the clip and provide a nice visual to the top of the pen

It's C, D, and E that I feel like, I just made up the terms for... what do you call those bits?