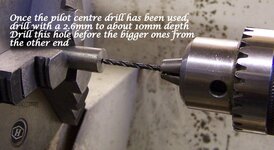

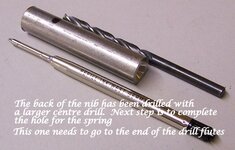

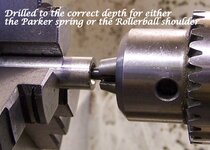

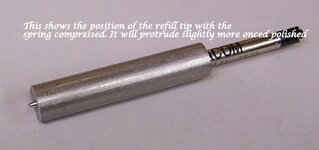

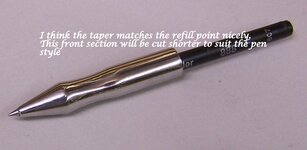

Here is a method ( pictorial ) I often use for making a stainless nib ( grip, front section, whatever :wink that can take either a Parker style refill or a Rollerball. There are loads of pics and maybe some can be deleted if they don't mean anything. I'll do another one soon for the threaded couplers and cap thread etc and another one for various styles of clips until this pen is finished.

that can take either a Parker style refill or a Rollerball. There are loads of pics and maybe some can be deleted if they don't mean anything. I'll do another one soon for the threaded couplers and cap thread etc and another one for various styles of clips until this pen is finished.

Hopefully it will give someone an idea or two on where to get started with their new metal lathe. The techniques I used may not be the best or correct way, but they are easy.:biggrin:

Hopefully it will give someone an idea or two on where to get started with their new metal lathe. The techniques I used may not be the best or correct way, but they are easy.:biggrin:

Attachments

Last edited: