PatrickR

Member

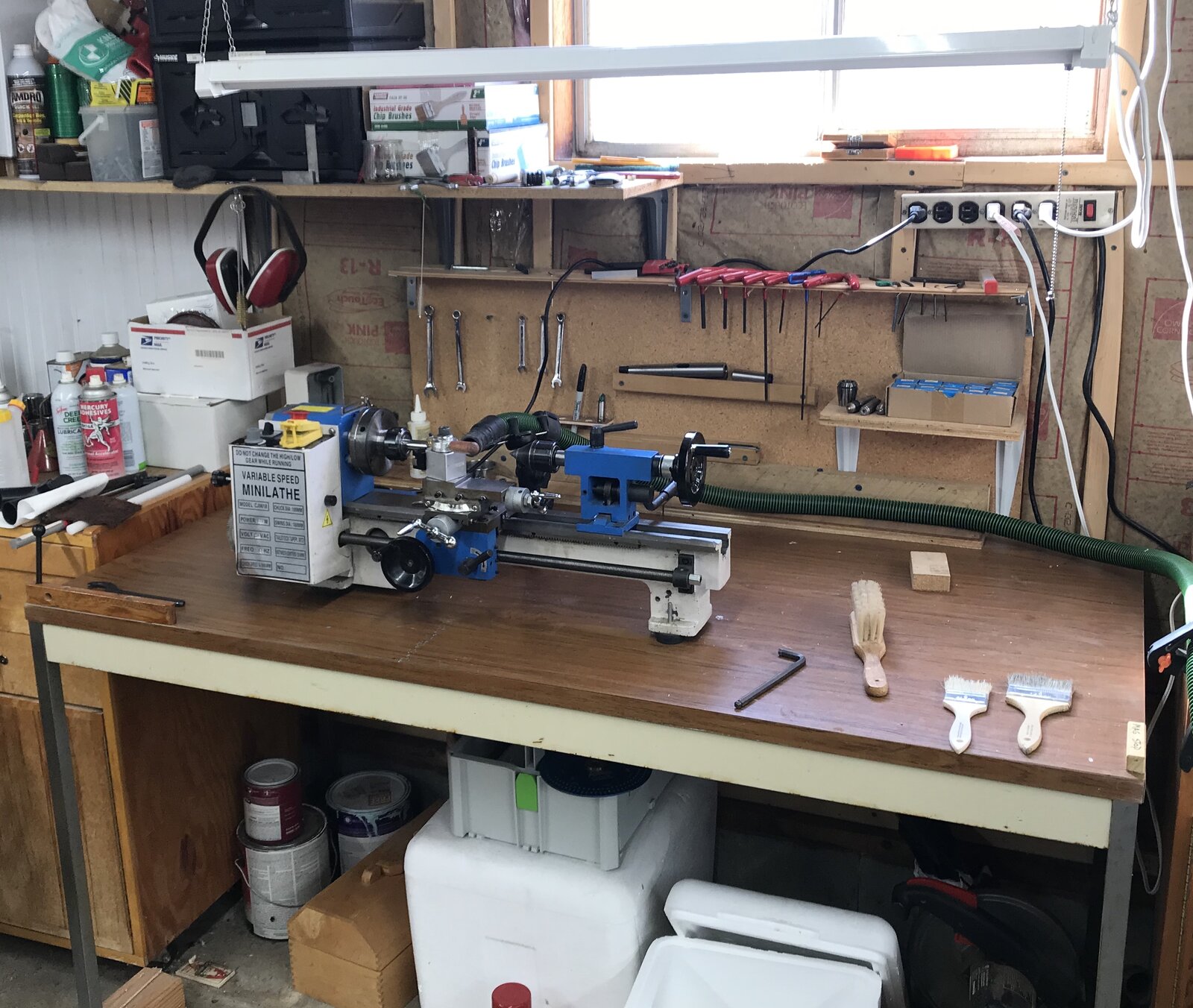

I purchased the Seig style lathe in 2017. It has been OK but that's all. Far from well made. After some research I went with the Proxxon PD 400. I have not used it yet, just completed the installation. Initial impression is very good. Night and day difference in fit and finish.

And a shot of the supervisor, Huck, the best shop dog I've had.

And a shot of the supervisor, Huck, the best shop dog I've had.