Nolan

Member

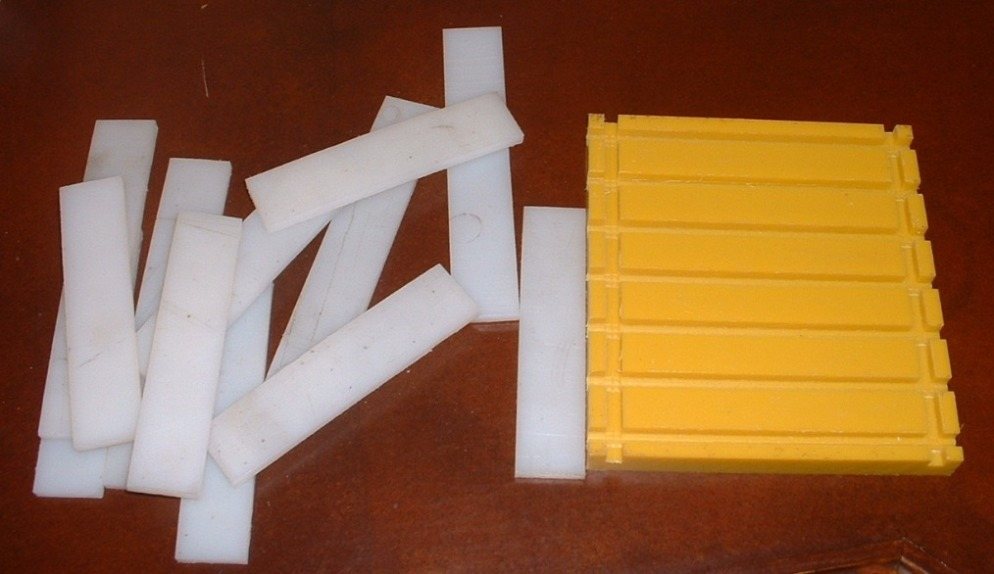

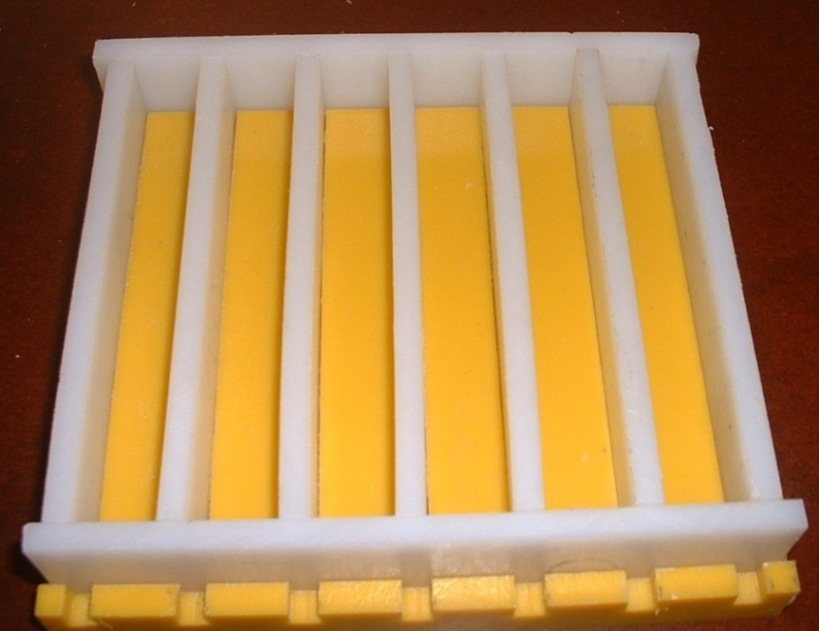

Well how about some opinions??? UHMW so the resin wont stick.

Originally posted by n4631x

<br />I built it like this because I am casting individual blanks with the tubes installed. If I was doing solid stuff then yah one big piece and cut the blanks out of that would be easier. I also have some block-offs with holes center (less the extra for the top so I dont spill. That way I can cast the half blanks with stoppers and centering /block-off pieces. Will post more pics as I got one ready to cast.