SabertoothBunny

Member

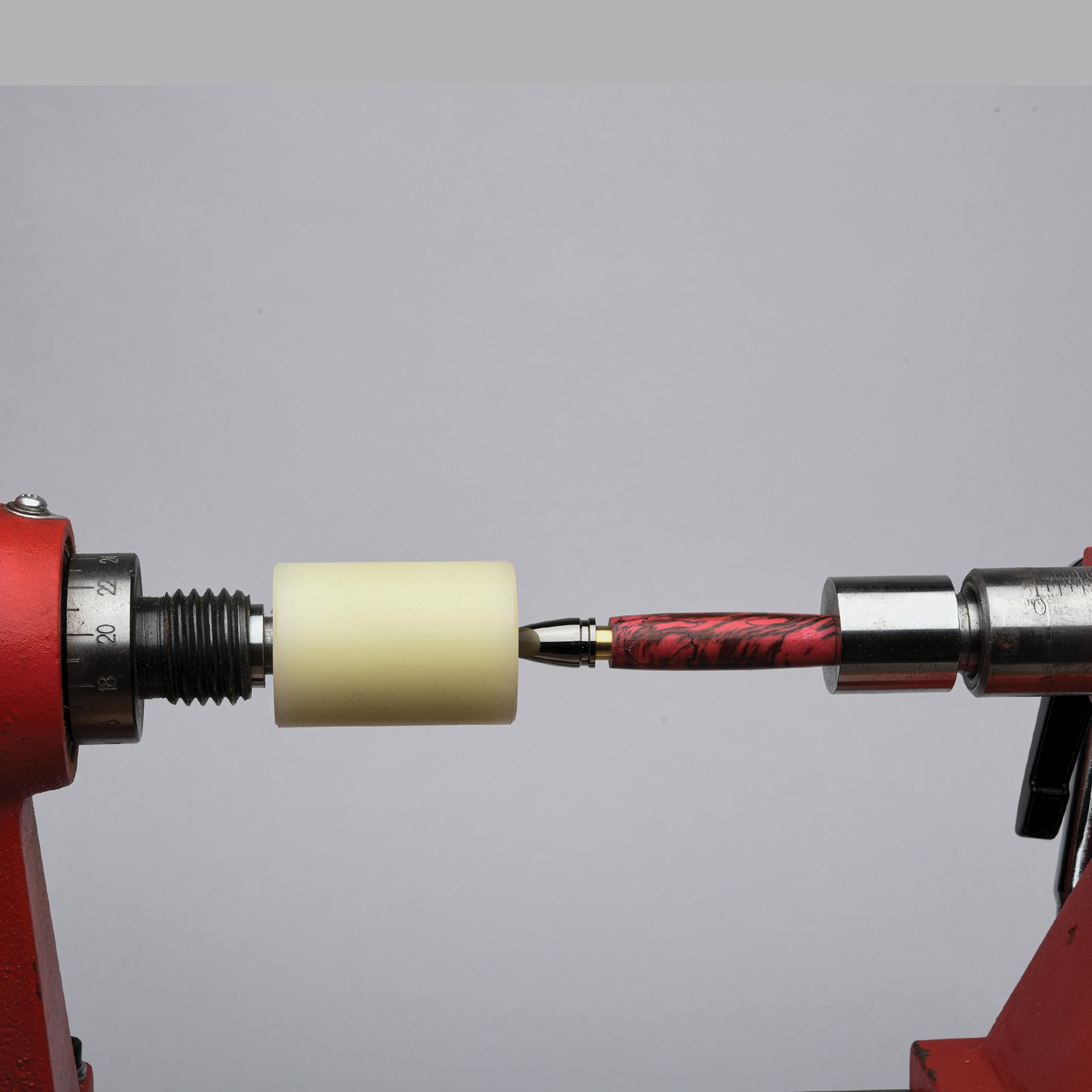

Rockler released their own version of a pen press (see link) and it is reasonably priced at $50. The press looks like a modified clamp but simple. Not sure if I am a fan of the twist style press though, the traditional press style seems easier and more efficient.

Just thought I would share this with everyone since I can across it. What are you thoughts?

www.rockler.com

www.rockler.com

Just thought I would share this with everyone since I can across it. What are you thoughts?

Rockler Pen Press

Fine threads apply precise, controlled pressure for smooth assembly and perfect alignment.