CaptG

Member

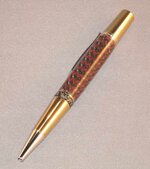

I have been working on carbon fiber blanks and been making progress. I got a piece of red and black material and noticed it was thicker than the black I have been using. I glued the cf to a tube that had been blackened with brass black. Then saturated tube with pr and gently worked in with small, firm brush. 48 hrs. later pr was hard and tube looked good, into mold and pressure pot it went, first 20 minutes at 30 vac. to degas, then pressured up to 40 psi for 48 hrs. inside warm house. Molds came out looking good, no fog, bubbles, or spots. Put blank on lathe and started turning, nice and easy. Turned to just over bushing size and started 600 grit light sand, then MM. As I got closer to finish, I stopped lathe to look at part and thats when the cussing started. Silver bubbles. Lots of silver bubbles. They were not there when I started, I mold inside clear round plastic tubes and cast is water clear out of the pot. When I removed blank from lathe, I decided to assemble just to get an idea what pen might look like. I hand start the first pc. and then finish in pen press. When I hand started the 1st. pc., it seemed to go in too easy, by hand. Upon looking, the tube had pushed out of the cf and was loose. Removing tube by hand and checking close, The brass black finish was on the cf, but had let go of the brass. Crapp. Next parts will be powder coated black and rough sanded before cf if applied. Picture is of pen put all back togather for photo purposes, so please ignore the dull finish. I stopped when I saw silver, not wanting to waste any more time. Pen has been dis-assembled and brass tube pulled out to save. Next one will be better. Has any one else had problem with tube comming loose using brass black? Thanks for listening.

Attachments

Last edited: