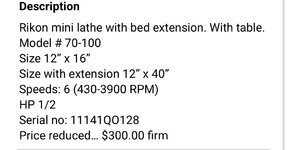

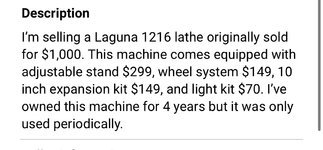

Evening, turned my first pen at a Rockler class last week. Have read about larger vs smaller lathes limitations and many people prefer variable speed vs belt. Not sure if I can post this here or where to.. Been lookin at getting lathe and various options. Could get a used Jet 1014 for $250.00. Or a new from Rockler

If anyone has other recommendations they have, would be happy to listen. Also with cost of needed tools, chucks and other necessities for pen turning. What's the average starting cost one typically spends? Lookin to pen turn and possibly make lidded boxes. Already own scroll saw, drill press, several hand saws. Thank you

If anyone has other recommendations they have, would be happy to listen. Also with cost of needed tools, chucks and other necessities for pen turning. What's the average starting cost one typically spends? Lookin to pen turn and possibly make lidded boxes. Already own scroll saw, drill press, several hand saws. Thank you

Last edited: