Gary Max

Member

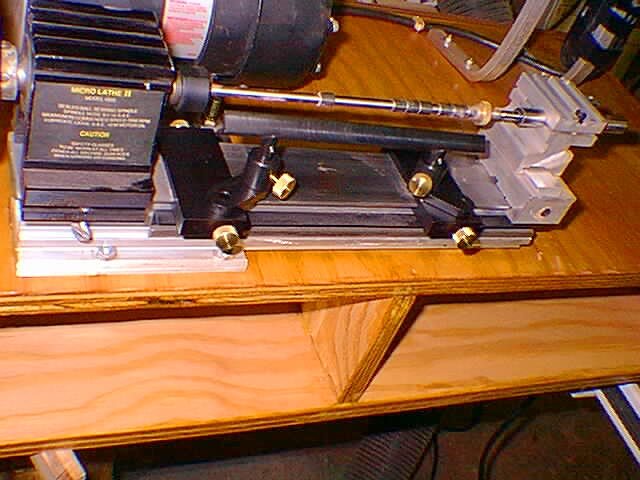

After months of work--buying parts--hunting for that Right motor.

She is done. Fed-ex dropped off the last parts today--they came from Lee Valley--(real nice folks)

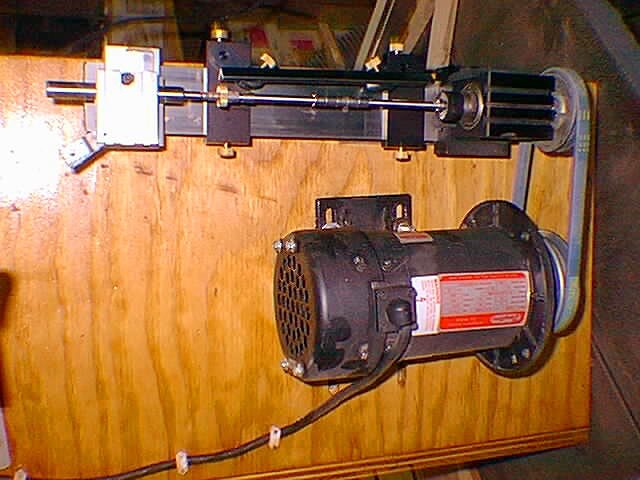

Motor is a Dayton 1/4 hp Dc with variable drive control

I went with the 7 inch tool rest as well.

As soon as I get the other projects that I am building done I am going to spend some time with my new lathe.

We ain't going to talk about how much money you can drop on these lathes-- I also have the metal lathe parts for the lathe.

She is done. Fed-ex dropped off the last parts today--they came from Lee Valley--(real nice folks)

Motor is a Dayton 1/4 hp Dc with variable drive control

I went with the 7 inch tool rest as well.

As soon as I get the other projects that I am building done I am going to spend some time with my new lathe.

We ain't going to talk about how much money you can drop on these lathes-- I also have the metal lathe parts for the lathe.