ldubia

Member

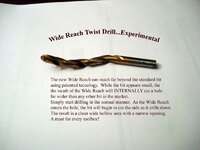

Here's one for everyone. Check out the new bit! The new Wide Reach! :biggrin: :biggrin:

:biggrin: :biggrin:

This happened on my lathe at slow speed, drilling a pen blank. The drill head got yanked out of the tailstock and got wrapped up in the toolrest. It broke the wood but not all the way. The drill was embedded in the wood. I had to pry it off after changing my shorts.

Has anyone ever had a morse taper let go like this? The taper is clean, free of dirt, etc as is the drill morse taper. I checked it after setting it to make sure it was tight. It would not budge. I was drilling cherry burl on a Turncrafter midi lathe.

This happened on my lathe at slow speed, drilling a pen blank. The drill head got yanked out of the tailstock and got wrapped up in the toolrest. It broke the wood but not all the way. The drill was embedded in the wood. I had to pry it off after changing my shorts.

Has anyone ever had a morse taper let go like this? The taper is clean, free of dirt, etc as is the drill morse taper. I checked it after setting it to make sure it was tight. It would not budge. I was drilling cherry burl on a Turncrafter midi lathe.

Last edited: