stevers

Member

Hi,

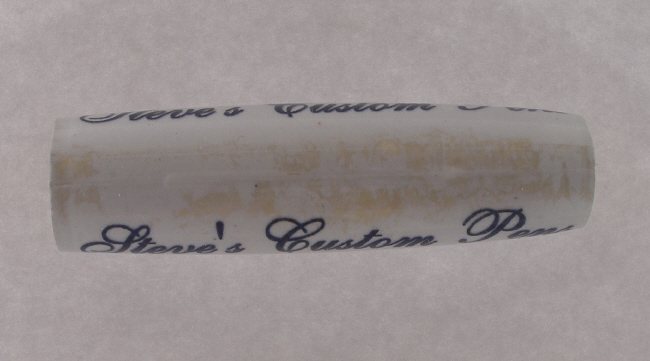

I turned down one of the blanks you saw me casting along with the Lilly blanks and had a catastrophic failure. I need to know if anyone has had this exact thing happen. It appears there was a reaction between the paint and glue on the labels. I suspect heat also, but my first thought is a reaction. The paint is Krylon, flat white, fast drying. The labels are Avery 8163 white mailing labels.

Come on Greg, Bruce, all of you, this is getting expensive.

I turned down one of the blanks you saw me casting along with the Lilly blanks and had a catastrophic failure. I need to know if anyone has had this exact thing happen. It appears there was a reaction between the paint and glue on the labels. I suspect heat also, but my first thought is a reaction. The paint is Krylon, flat white, fast drying. The labels are Avery 8163 white mailing labels.

Come on Greg, Bruce, all of you, this is getting expensive.