Dale Allen

Member

I need to know if there is interest in this before I do much of a writeup.

Since I now prefer to turn my pen blanks round before drilling, I struggle with this task. The tools I have purchased for this do not work well enough for me so I have made something different.

This is a piece of modeling plastic cut to 1" square and about 7" long.

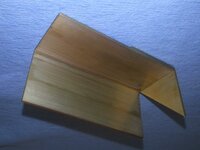

I have created a 90 degree pocket in 2 pieces about 2" long with a pin extending from the top that is directly over where the corner of the blank would be.

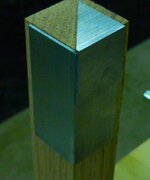

With the corner pieces set on opposite corners, I hold a small steel ruler up against the pins and mark the center by drawing a short line in both directions.

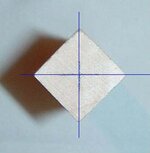

This works on those blanks that are not precisely square and that may have a ragged edge. I took a picture of a marked blank and drew lines in a drawing program over the corners. It appears to work rather well.

At least now I do not need to bother making the blank square before marking the center. I will test one of the marked blanks tomorrow by drilling center bit holes in the end and turning it down part way.

I'm sure some refinement ideas are out there among the group. Let me know what you think and if this can be improved on, I'm all ears...or eyes! :biggrin:

Since I now prefer to turn my pen blanks round before drilling, I struggle with this task. The tools I have purchased for this do not work well enough for me so I have made something different.

This is a piece of modeling plastic cut to 1" square and about 7" long.

I have created a 90 degree pocket in 2 pieces about 2" long with a pin extending from the top that is directly over where the corner of the blank would be.

With the corner pieces set on opposite corners, I hold a small steel ruler up against the pins and mark the center by drawing a short line in both directions.

This works on those blanks that are not precisely square and that may have a ragged edge. I took a picture of a marked blank and drew lines in a drawing program over the corners. It appears to work rather well.

At least now I do not need to bother making the blank square before marking the center. I will test one of the marked blanks tomorrow by drilling center bit holes in the end and turning it down part way.

I'm sure some refinement ideas are out there among the group. Let me know what you think and if this can be improved on, I'm all ears...or eyes! :biggrin: