Si90

Member

I made this pen more of a proof of concept/practice piece to trial a couple of new techniques and materials - It's not my most favourite pen I have made, but in terms of the materials etc it's the one thats cost me the most to make.

The first thing is that it's the first pen I have fully silver soldered. This gives nice joints but does bring with it a few things to consider. The melting point is 660 to 730°C - thats hot and its's low temp solder. When you consider that there are a lot of joints in close proximity with very light weight/thin walled brass its's very easy to destroy the brass.

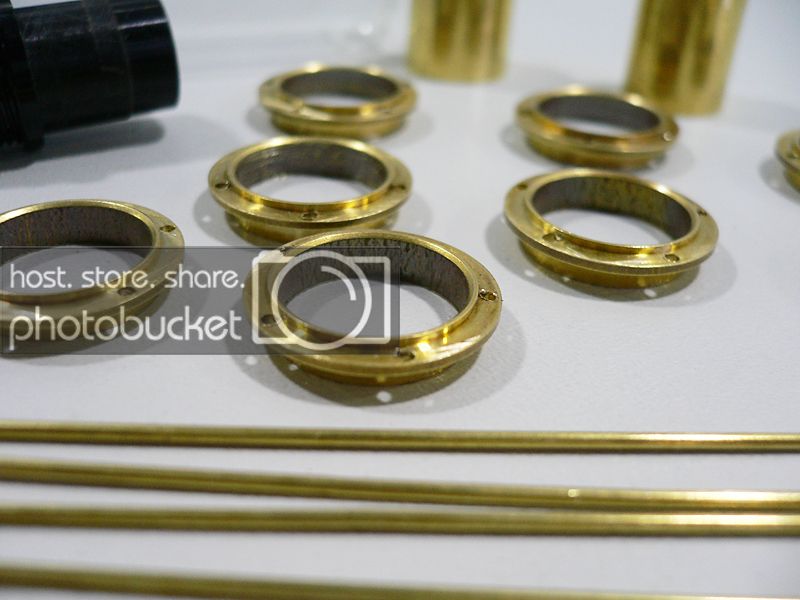

The rings around the pen are actually brass portholes intended for model boats. Each ring is 2 portholes soldered together.

The other issue is that it's almost impossible to stop brass from tarnishing. They look great polished but it would take a small amount of effort on the owners part to maintain this. I wanted to try and embrace the aged look and if possible enhance it so that you don't feel you have to keep it polished. I bent the thin rails and the ends of the tubes a few times to make them look old, used and beaten up. The pen was polished and then strategically heated to give it the aged look.

It's proved to me that I have to invest in a better way of holding parts firmly in position while soldering. Some of the parts moved so the cap isn't as straight or inline as well as I would have liked but again its made in "used condition"

My final conclusion is as my friend "Mr Skiprat" likes to keep reminding me

I would find it a lot easier to realise my ideas if I went kitless and had a metal lathe and mill. It's quite difficult, but not impossible to make some of the things I imagine out of stock pieces of brass and make them fit the kit parts I am using. Maybe thats for the future but for now here it is.

I would find it a lot easier to realise my ideas if I went kitless and had a metal lathe and mill. It's quite difficult, but not impossible to make some of the things I imagine out of stock pieces of brass and make them fit the kit parts I am using. Maybe thats for the future but for now here it is.

As always thanks for taking the time to look at my efforts. Sorry for a couple of the pics that are out of focus.

The first thing is that it's the first pen I have fully silver soldered. This gives nice joints but does bring with it a few things to consider. The melting point is 660 to 730°C - thats hot and its's low temp solder. When you consider that there are a lot of joints in close proximity with very light weight/thin walled brass its's very easy to destroy the brass.

The rings around the pen are actually brass portholes intended for model boats. Each ring is 2 portholes soldered together.

The other issue is that it's almost impossible to stop brass from tarnishing. They look great polished but it would take a small amount of effort on the owners part to maintain this. I wanted to try and embrace the aged look and if possible enhance it so that you don't feel you have to keep it polished. I bent the thin rails and the ends of the tubes a few times to make them look old, used and beaten up. The pen was polished and then strategically heated to give it the aged look.

It's proved to me that I have to invest in a better way of holding parts firmly in position while soldering. Some of the parts moved so the cap isn't as straight or inline as well as I would have liked but again its made in "used condition"

My final conclusion is as my friend "Mr Skiprat" likes to keep reminding me

As always thanks for taking the time to look at my efforts. Sorry for a couple of the pics that are out of focus.