Mike

Member

Just finished this yesterday, I think it turned out pretty good.

It is 14" by 20" by 1.5".

From the wide center piece out, boards are Maple, Brazilian Cherry, American Cherry, Maple, Walnut, American Cherry, Maple,Walnut, Maple, and Brazilian Cherry. I think I got that right???

My son researched cutting board finishes and decided on this one, so I went with it. He is a very thorough man.

I finished one side with Milk Paint Half and Half per the instructions on the container. It is made from Pure Tung Oil and natural, food-grade thinner Citrus Solvent.

I let it sit overnight and did the other side, again letting it sit over night.

I then waxed it with Boos Block Board Wax, heavy coat, let sit overnight, etc.

I don't think the heavy coat was necessary, wax does not soak in after the Half and Half, and maybe not before.

My planer is a Delta 13", so I glued it up in 2 parts then scraped all the glue off and planed both pieces evenly until all the uneven surfaces were gone.

I then glued the 2 parts together, being very careful that they were even.

After removing the glue, top and bottom were within a few thousandths of an inch.

A lot of sanding with the mouse, some routing and more sanding and finishing.

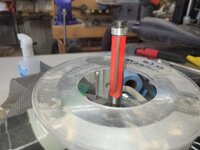

First pic is the final glue up of the 2 parts. Then the router bit I used for the corners. A pic of the corner with the router template underneath.

See pics here.

Thoughts, criticism, praise, say what you think.

Thanks,

Mike

It is 14" by 20" by 1.5".

From the wide center piece out, boards are Maple, Brazilian Cherry, American Cherry, Maple, Walnut, American Cherry, Maple,Walnut, Maple, and Brazilian Cherry. I think I got that right???

My son researched cutting board finishes and decided on this one, so I went with it. He is a very thorough man.

I finished one side with Milk Paint Half and Half per the instructions on the container. It is made from Pure Tung Oil and natural, food-grade thinner Citrus Solvent.

I let it sit overnight and did the other side, again letting it sit over night.

I then waxed it with Boos Block Board Wax, heavy coat, let sit overnight, etc.

I don't think the heavy coat was necessary, wax does not soak in after the Half and Half, and maybe not before.

My planer is a Delta 13", so I glued it up in 2 parts then scraped all the glue off and planed both pieces evenly until all the uneven surfaces were gone.

I then glued the 2 parts together, being very careful that they were even.

After removing the glue, top and bottom were within a few thousandths of an inch.

A lot of sanding with the mouse, some routing and more sanding and finishing.

First pic is the final glue up of the 2 parts. Then the router bit I used for the corners. A pic of the corner with the router template underneath.

See pics here.

Thoughts, criticism, praise, say what you think.

Thanks,

Mike

Attachments

Last edited: