Hey Fellow turners!

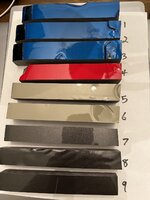

Here is another batch of sweet Fordite, mostly Jeep. Fordite is becoming more and more rare because they use different paint methods now sooo... get it while its HOT. These pieces are super nice and some have paint ripples and inclusions. The inclusions will need a practiced hand and careful stabilizing with CA glue, epoxy, or other...you know the drill.

1. Approx 7/8in sq. by 5.5 inches- $40

2. Approx 7/8 in sq. by 6 inches- $45

3. Approx 7/8 in sq.by 6 inches- $45

4. Approx 7/8 in sq. by 5.5 inches- $40

5.Approx 7/8 in sq. by 5.5 inches- $40

6. Approx 7/8 in sq. by 5.5 inches- $40

7. Approx 3/4 in sq. by 5.75 inches- $35

8. Approx 3/4 in sq. by 6 inches- $35

9. Approx 3/4 in sq. by 5.75 inches- $35

Shipping $5, paypal accepted

Claim below and I'll send a message!

I'll wait a week or so before I post these on other forums.

My best,

Ben

Here is another batch of sweet Fordite, mostly Jeep. Fordite is becoming more and more rare because they use different paint methods now sooo... get it while its HOT. These pieces are super nice and some have paint ripples and inclusions. The inclusions will need a practiced hand and careful stabilizing with CA glue, epoxy, or other...you know the drill.

1. Approx 7/8in sq. by 5.5 inches- $40

2. Approx 7/8 in sq. by 6 inches- $45

3. Approx 7/8 in sq.by 6 inches- $45

4. Approx 7/8 in sq. by 5.5 inches- $40

5.Approx 7/8 in sq. by 5.5 inches- $40

6. Approx 7/8 in sq. by 5.5 inches- $40

7. Approx 3/4 in sq. by 5.75 inches- $35

8. Approx 3/4 in sq. by 6 inches- $35

9. Approx 3/4 in sq. by 5.75 inches- $35

Shipping $5, paypal accepted

Claim below and I'll send a message!

I'll wait a week or so before I post these on other forums.

My best,

Ben