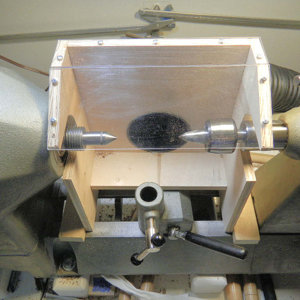

Finally got around to hooking up some better dust collection for my lathe. I already had the dust collector that I had made portable. Even had the pvc pipe. I just needed some fittings, brackets and Tapcon screws. It works amazingly well. Everything to the right of the top elbow is not cemented so I can alter the configuration, if need be.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lathe dust collection

- Thread starter KenB259

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

howsitwork

Member

Ken

looks good . Might be worth getting one of the dust hood type arrangements for it?

looks good . Might be worth getting one of the dust hood type arrangements for it?

MRDucks2

Member

Seems I recently read or watched something which showed a dust collection intake that was round actually outperformed a larger baffle on the lathe. Will try to find it, but it was quite convincing.

I'll probably leave it as is, it really works wellSeems I recently read or watched something which showed a dust collection intake that was round actually outperformed a larger baffle on the lathe. Will try to find it, but it was quite convincing.

Woodchipper

Member

Looks good. My Shop Vac isn't quite enough to slurp in the dust and shavings. So...my dust collection system is slurping everything off the lathe and floor.

sorcerertd

Member

I recall seeing something a while back also. They were talking about how much of a difference the airflow was with a small flare on the end, too.Seems I recently read or watched something which showed a dust collection intake that was round actually outperformed a larger baffle on the lathe. Will try to find it, but it was quite convincing.

RichAldrich

Member

I like it!

randyrls

Member

Curly

Member

That would be a bell mouth hood.Seems I recently read or watched something which showed a dust collection intake that was round actually outperformed a larger baffle on the lathe. Will try to find it, but it was quite convincing.

Larryreitz

Member

Thanks for posting this. I need to implement some kind of dust collector and this looks like a good way to go.

I should have done it long before now. Thing is I tried various methods all based on just a shop vac and none were very effective. I didn't realize my portable dust collector quick connect would attach to pvc pipe so easily. Soon as I realized that, the rest was a no brained.Thanks for posting this. I need to implement some kind of dust collector and this looks like a good way to go.

MRDucks2

Member

Yep! That was it. Well done, Peter.That would be a bell mouth hood.

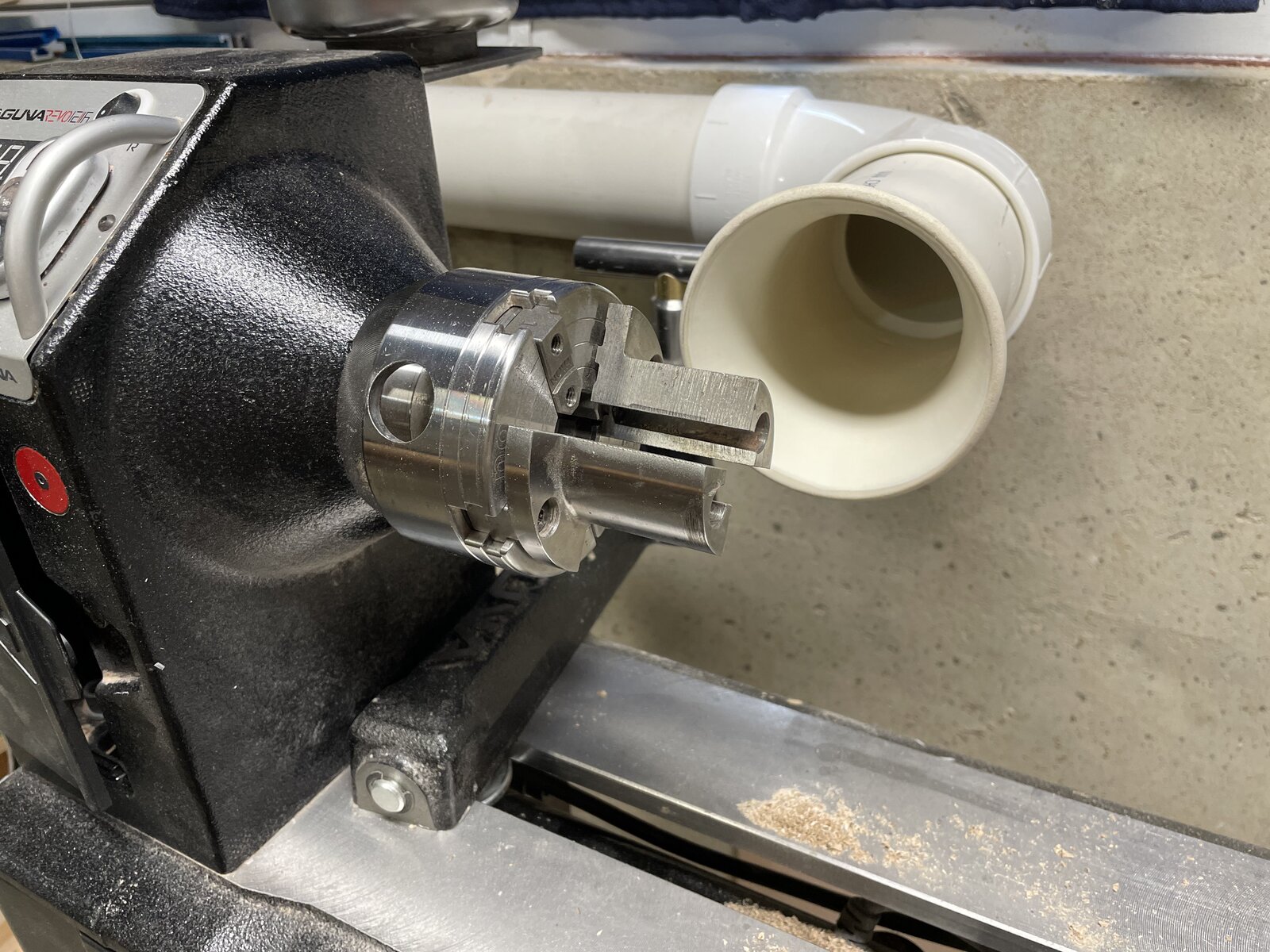

Just an update. I took Curly's advice and formed a piece of pvc as much as I could. Made my little setup even better. I don't begin to understand the science behind it but it does seem to pull in dust from a wider area. I just chucked up the pvc , set the late to the slowest speed it had and held a heat gun on it until it was pliable and then pushed it down over a 2 liter pop bottle.

Nice little setup! I like how it stays put!  I have tried a number of flexible, positionable solutions, which never quite worked. I recently picked up a lathe rail system. Much better than my own rigged up solutions, but...even that, doesn't quite "stay put" and still drifts a little. This is for my bigger lathe, the Powermatic, so I do need some maneuverability. Still, a system that kept the intake right where you put it would be nice.

I have tried a number of flexible, positionable solutions, which never quite worked. I recently picked up a lathe rail system. Much better than my own rigged up solutions, but...even that, doesn't quite "stay put" and still drifts a little. This is for my bigger lathe, the Powermatic, so I do need some maneuverability. Still, a system that kept the intake right where you put it would be nice.

I am curious about something... First, you ever notice a big static buildup on your PVC there? I've been planning to build out my own dust collection for my workshop this summer, and one of the big factors I found was static charge with PCV. I'm curious if you've grounded yours to drain off the charge or anything like that.

I have been planning on running 6" ducting throughout my garage, then converted to 4" flex tube for the devices that require 4", and getting some kind of 6" tube to connect to my lathes. I figured I'd use a bell mouth hood, as Pete recommended that when I last asked about this stuff earlier in the year. I've been concerned about the dust buildup and potential static charge/dust ignition/explosion. Where I would have to run my ducting, it would inevitably have to pass by, at least in a few places, my natural gas line. I've kind of walled that off with some wood, but...still, I'm concerned about static charge as the gas line is also metal. The metal ducting is a lot more expensive, although it sounds like it has much less of a problem with any static charge buildup. The PVC piping is much cheaper...but then I'd have to figure out a reliable way to drain off all the charge that can build up on it... Its been my great internal debate of 2022 so far...

I am curious about something... First, you ever notice a big static buildup on your PVC there? I've been planning to build out my own dust collection for my workshop this summer, and one of the big factors I found was static charge with PCV. I'm curious if you've grounded yours to drain off the charge or anything like that.

I have been planning on running 6" ducting throughout my garage, then converted to 4" flex tube for the devices that require 4", and getting some kind of 6" tube to connect to my lathes. I figured I'd use a bell mouth hood, as Pete recommended that when I last asked about this stuff earlier in the year. I've been concerned about the dust buildup and potential static charge/dust ignition/explosion. Where I would have to run my ducting, it would inevitably have to pass by, at least in a few places, my natural gas line. I've kind of walled that off with some wood, but...still, I'm concerned about static charge as the gas line is also metal. The metal ducting is a lot more expensive, although it sounds like it has much less of a problem with any static charge buildup. The PVC piping is much cheaper...but then I'd have to figure out a reliable way to drain off all the charge that can build up on it... Its been my great internal debate of 2022 so far...

Curly

Member

You cannot build a high enough static electric charge in any home dust collector that will ignite dust. I addition you need to be producing close to a pound of fine dust every minute to have and maintain an explosive concentration of the dust to ignite. None if us have that capability. The two reasons you want to do something about static is the shock you might startle you and make you jerk into a spinning turning or saw blade etc. The second is that the static discharge can damage sensitive electronics in the shop. A CNC controller for example. Since PVC is an insulator it is very hard to ground as any wire wrapped around the duct will only remove the static a fraction of an inch away so the majority is still charged.

One thing you could try is a static dissipating finish painted onto the ducting. Haven't tried it personally. It is commonly used in electronics labs to remove the static on the floors and benches. https://www.aclstaticide.com/products/staticide-acrylic

Pete

Pete

I haven't had it hooked up to long but I haven't noticed any static electricity problems so far.Nice little setup! I like how it stays put!I have tried a number of flexible, positionable solutions, which never quite worked. I recently picked up a lathe rail system. Much better than my own rigged up solutions, but...even that, doesn't quite "stay put" and still drifts a little. This is for my bigger lathe, the Powermatic, so I do need some maneuverability. Still, a system that kept the intake right where you put it would be nice.

I am curious about something... First, you ever notice a big static buildup on your PVC there? I've been planning to build out my own dust collection for my workshop this summer, and one of the big factors I found was static charge with PCV. I'm curious if you've grounded yours to drain off the charge or anything like that.

I have been planning on running 6" ducting throughout my garage, then converted to 4" flex tube for the devices that require 4", and getting some kind of 6" tube to connect to my lathes. I figured I'd use a bell mouth hood, as Pete recommended that when I last asked about this stuff earlier in the year. I've been concerned about the dust buildup and potential static charge/dust ignition/explosion. Where I would have to run my ducting, it would inevitably have to pass by, at least in a few places, my natural gas line. I've kind of walled that off with some wood, but...still, I'm concerned about static charge as the gas line is also metal. The metal ducting is a lot more expensive, although it sounds like it has much less of a problem with any static charge buildup. The PVC piping is much cheaper...but then I'd have to figure out a reliable way to drain off all the charge that can build up on it... Its been my great internal debate of 2022 so far...

You would need more than just wire wrapped around the PVC. It actually needs to be legit grounded. As in to an electrical system ground, one way or another. Further, dissipating the external static charge doesn't help with the internal static charge, which is more risky. I found this thread helpful in the past:You cannot build a high enough static electric charge in any home dust collector that will ignite dust. I addition you need to be producing close to a pound of fine dust every minute to have and maintain an explosive concentration of the dust to ignite. None if us have that capability. The two reasons you want to do something about static is the shock you might startle you and make you jerk into a spinning turning or saw blade etc. The second is that the static discharge can damage sensitive electronics in the shop. A CNC controller for example. Since PVC is an insulator it is very hard to ground as any wire wrapped around the duct will only remove the static a fraction of an inch away so the majority is still charged.One thing you could try is a static dissipating finish painted onto the ducting. Haven't tried it personally. It is commonly used in electronics labs to remove the static on the floors and benches. https://www.aclstaticide.com/products/staticide-acrylic

Pete

PVC Static Buildup Explosions?

Definite or Doubt, this has been going around the forums for ages. Does PVC cause static buildup? And if so, can it cause a dangerous explosion? Here's some facts. PVC does in fact, cause static buildup with sawdust. Ever vacuum with your shop vac and notice toward the end of the hose there's a...

It may be a rare occurrence, but it can happen, where you get a discharge and ignite something. As the guy cabinetman states, you may have never been in a car accident, or may not know anyone who has, but you still wear your seatbelt.

The point about more sensitive electronics is good, though. I also just don't like getting zapped as I move through my shop. I have had a few nasty ones, even with the pitiful shop vac setup I currently have. Usually with the finer dust, it seems to create a fairly significant charge.

I also guess I'm less concerned about actually blowing up my garage, as I am about just igniting the dust and having a fire, which could be quite devastating in and of itself.

Aurelius

Member

Slightly off topic question, but do you notice any loss from the extra elbow? What I mean is, I would have thought you would go back from the lathe to a right angle, then straight down, and then have the attachment to the hose there at the bottom. Instead you are coming off sideways and I would htink that could lead to dust settlign in the horizontal section of just generally decreasing your suction power.

Slightly off topic question, but do you notice any loss from the extra elbow? What I mean is, I would have thought you would go back from the lathe to a right angle, then straight down, and then have the attachment to the hose there at the bottom. Instead you are coming off sideways and I would htink that could lead to dust settlign in the horizontal section of just generally decreasing your suction

I don't notice any lack of suction, if there is, doesn't matter because it works very well.