Fangar

Member

Hey Guys,

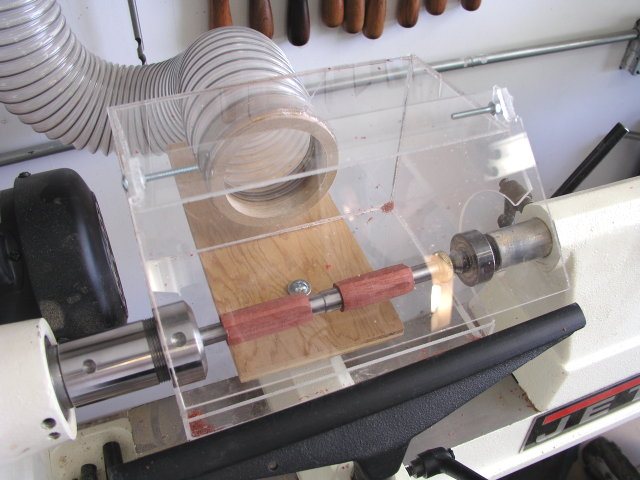

I was looking into various Dust Collection Hoods / Ports for my new lathe and Dust Collection setup. I decided that none offered for sale, had quite the position and setup that I wanted. I made one out of Acrylic that I got from Tap Plastic's scrap bin for $2.50. I had the scrap wood on hand, so I guess I only paid around 3 bucks for it. I had fun designing it.

This photo shows the port in place with the shield up.

Shield down. You can run it either way, but if doing some of the more explosive acrylics, it works pretty well...

This photo shows the 4" collection connector that I turned on the lathe out of MDF. It was a snug fit, but all of the joints were sealed with thick CA. Epoxy would work too.

Finally, this photo shows the stand. Sturdy enough. I can also place a weight on the foot if needed, but it seems to be quite sturdy.

Anyway, thought I would share. I works great. Especially for 3 bucks! I am planning on making another one that will bolt to the same base for larger items.

Cheers,

Fangar

I was looking into various Dust Collection Hoods / Ports for my new lathe and Dust Collection setup. I decided that none offered for sale, had quite the position and setup that I wanted. I made one out of Acrylic that I got from Tap Plastic's scrap bin for $2.50. I had the scrap wood on hand, so I guess I only paid around 3 bucks for it. I had fun designing it.

This photo shows the port in place with the shield up.

Shield down. You can run it either way, but if doing some of the more explosive acrylics, it works pretty well...

This photo shows the 4" collection connector that I turned on the lathe out of MDF. It was a snug fit, but all of the joints were sealed with thick CA. Epoxy would work too.

Finally, this photo shows the stand. Sturdy enough. I can also place a weight on the foot if needed, but it seems to be quite sturdy.

Anyway, thought I would share. I works great. Especially for 3 bucks! I am planning on making another one that will bolt to the same base for larger items.

Cheers,

Fangar