Dale Allen

Member

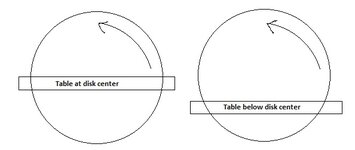

With rare exceptions, I see these designs patterned after the dedicated units in that the table is set at the center of the disk.

I use a small 6" one that I made years ago and it is set about 1" below center. Until I started planing a bigger unit, I had not given this much thought.

There are a lot of manufactured ones that even have a guard on the back half of the disk.

Is there a reason they are set up this way?

My though is that on the front half the disk is pushing down toward the table and at the back it is pushing up. So that in fact may contribute to an uneven sanded surface on my small one when I run the piece back and forth across the center-line. Even trying to hold the piece flat to the table, it may still be moving off square.

Thanks for any insights.

I use a small 6" one that I made years ago and it is set about 1" below center. Until I started planing a bigger unit, I had not given this much thought.

There are a lot of manufactured ones that even have a guard on the back half of the disk.

Is there a reason they are set up this way?

My though is that on the front half the disk is pushing down toward the table and at the back it is pushing up. So that in fact may contribute to an uneven sanded surface on my small one when I run the piece back and forth across the center-line. Even trying to hold the piece flat to the table, it may still be moving off square.

Thanks for any insights.