hooked

Member

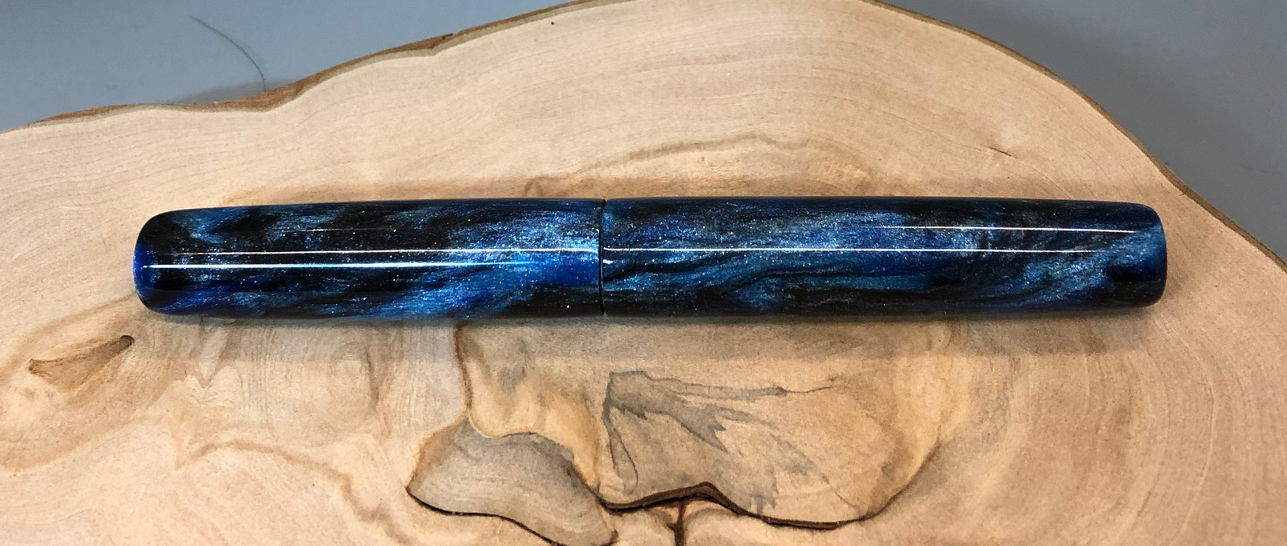

Hi. I just finished my first kitless pen. I had a blast figuring this one out and can see why this is addicting. I recently joined in on the IAP tap/die group buy and wanted to get some practice while waiting for my order. So I purchased some cheaper single start taps/die to get an idea of what is involved.

My first attempt, I think, was pretty good. However, I did encounter some issues and had a few questions that I am hoping to ask.

1- What is the best lubricant for tap/die use? I used Renaissance Wax on my first pen. I notice that my threads look very "raw," It seems pretty apparent that I shouldn't sand or mess with the threads too much. Is there a method or lubricant to get cleaner-looking threads? I cut my tenon, chamfered the tenon, applied a liberal amount of renaissance wax to the tenon and die, ran the die, flipped the die, and reran it.

2- I noticed that my Jowo #6 tap is M7.5 x .5. When I was looking online, I saw that another online retailer sells a Jowo #6 tap that is M7.4 x .5. The nib seems to fit fine, perhaps not quite as tight as the cap threads, but I assumed it was sloppy tapping. I do want to be sure I have the right tap. Can someone verify, please?

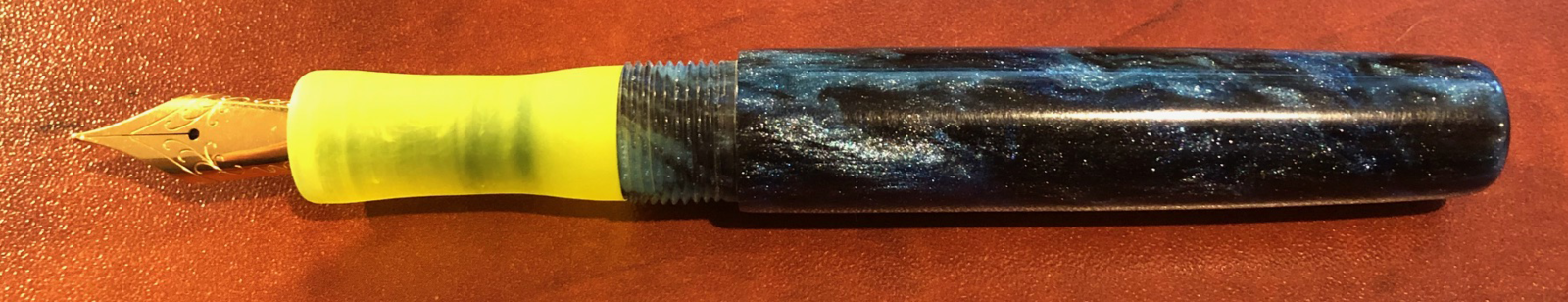

3- I am not a fountain pen user and did not order ink supplies. Does the section need to be as long as I made it? I have made another section with neon yellow material to see through. Does there need to be so much space behind the nib? I find that my cap fits right up against the nib's tip, and I think if I shortened the section a bit, it would fit better. Maybe less threads on the body for the cap would be better?

Thank you for any advice!

M14 x 1

M11 x .75

Jowo #6

My first attempt, I think, was pretty good. However, I did encounter some issues and had a few questions that I am hoping to ask.

1- What is the best lubricant for tap/die use? I used Renaissance Wax on my first pen. I notice that my threads look very "raw," It seems pretty apparent that I shouldn't sand or mess with the threads too much. Is there a method or lubricant to get cleaner-looking threads? I cut my tenon, chamfered the tenon, applied a liberal amount of renaissance wax to the tenon and die, ran the die, flipped the die, and reran it.

2- I noticed that my Jowo #6 tap is M7.5 x .5. When I was looking online, I saw that another online retailer sells a Jowo #6 tap that is M7.4 x .5. The nib seems to fit fine, perhaps not quite as tight as the cap threads, but I assumed it was sloppy tapping. I do want to be sure I have the right tap. Can someone verify, please?

3- I am not a fountain pen user and did not order ink supplies. Does the section need to be as long as I made it? I have made another section with neon yellow material to see through. Does there need to be so much space behind the nib? I find that my cap fits right up against the nib's tip, and I think if I shortened the section a bit, it would fit better. Maybe less threads on the body for the cap would be better?

Thank you for any advice!

M14 x 1

M11 x .75

Jowo #6