Sandy H.

Member

After a long hiatus from turning due to work, I got some time over the holidays to turn a few. Most turned out fairly well, but I have 2 that I noticed a problem I hadn't seen before. Attached are some pictures.

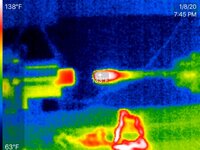

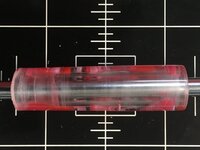

Starting with the purple one, overall, from 1 foot, it looks fine. Up close, cracks are visible from the inside out (it seems). I tried to get close-up pictures by shining a light to highlight the cracks. They actually look much worse this way than in just ambient light.

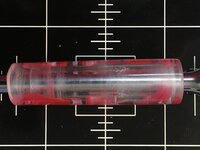

I went back to look at the yellow one, which I initially rejected due to what I thought were radial grooves left by the drilling process, but upon closer inspection, I think these are the same type of cracks.

By looking at the paint penetration, it seems that they start at the drilled hole and make it only part of the way through the blank due to the pain absorption, however I could easily believe this is just a coincidence and the paint was not able to wick up the cracks further. I cannot feel any cracking on the outside of either blank with my fingernail, but it is possible that the sanding and buffing would make it hard to feel anyway.

My assumption is that during the drilling process, the blank got hot and caused cracking. I am surprised by this, as I drilled on the lathe at 500 rpm and cleared the drill-bit often. I grab the drill tip after each drilling step and it was warm at most and not hot - definitely not hot enough to cause any discomfort when grabbing the tip, so less than 120-130 deg F for sure.

I painted the inside of the blanks with water based acrylic paint and used 2 part epoxy to attach the tube the the blank, so I don't think any sort of chemical reaction was the cause.

I wanted to ask if anyone had other thoughts as to the cause and any remedy other than taking smaller bites and cooling with water more often. Regretfully, I've drilled a few others using the same method already, so I might have the same scenario on more blanks. . .

Thanks for any suggestions.

Sandy.

Starting with the purple one, overall, from 1 foot, it looks fine. Up close, cracks are visible from the inside out (it seems). I tried to get close-up pictures by shining a light to highlight the cracks. They actually look much worse this way than in just ambient light.

I went back to look at the yellow one, which I initially rejected due to what I thought were radial grooves left by the drilling process, but upon closer inspection, I think these are the same type of cracks.

By looking at the paint penetration, it seems that they start at the drilled hole and make it only part of the way through the blank due to the pain absorption, however I could easily believe this is just a coincidence and the paint was not able to wick up the cracks further. I cannot feel any cracking on the outside of either blank with my fingernail, but it is possible that the sanding and buffing would make it hard to feel anyway.

My assumption is that during the drilling process, the blank got hot and caused cracking. I am surprised by this, as I drilled on the lathe at 500 rpm and cleared the drill-bit often. I grab the drill tip after each drilling step and it was warm at most and not hot - definitely not hot enough to cause any discomfort when grabbing the tip, so less than 120-130 deg F for sure.

I painted the inside of the blanks with water based acrylic paint and used 2 part epoxy to attach the tube the the blank, so I don't think any sort of chemical reaction was the cause.

I wanted to ask if anyone had other thoughts as to the cause and any remedy other than taking smaller bites and cooling with water more often. Regretfully, I've drilled a few others using the same method already, so I might have the same scenario on more blanks. . .

Thanks for any suggestions.

Sandy.