You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How do you trim your barrels?

- Thread starter TonyL

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

longbeard

Member

I do mine on the lathe Tony using my faceplate with a scrap piece of wood attached.

Harry

Harry

NittanyLion

Member

Ditto.

I do mine on the lathe Tony using my faceplate with a scrap piece of wood attached.

Harry

Dan Masshardt

Member

Almost all of the above.

The best 'other' that on aware of is trimming the ends on the lathe using a turning tool. Very solid method.

The best 'other' that on aware of is trimming the ends on the lathe using a turning tool. Very solid method.

magier412

Member

I'm with Dan...I pretty much use whatever is convenient at the time. Seems like the disc sander is handy usually.

southernclay

Member

Either scroll chuck and trim ends with parting tool or carbide or on lathe with sanding plate and Rick Herrells adjustable sanding jig. Occasionally use the pen mill.

JimB

Member

I use all methods listed depending on how much material needs to be removed but I do the final trim on the lathe with a sanding plate (home made), chuck and rod so I get it perfectly square.

Donovan

Member

After my blanks (tube in) have been turned round but are still oversize, I trim the ends in my metal-working lathe using a cutting toolbit .... I guess that doesn't count for your survey :biggrin: !

I also use my metal lathe

kingkeyman

Member

Rick Herrells jig and a scrapwood sanding disk for me. I threw away my pen mill.

cal91666

Member

Barrel trimmer and Rich Herrell's sanding mill.

flyitfast

Member

I used to use a belt sander, but now I use my new Jet 12" disk sander. I like the accuracy better. I have a jig that has been shown many times here on IAP.

Sanding on the lathe is a good way and not too different than using a disk sander with a transfer punch in a jig.

Never could get the hang of the barrel trimmer - ruined too many blanks because of the aggressiveness. Always needed sharpening.

gordon

Sanding on the lathe is a good way and not too different than using a disk sander with a transfer punch in a jig.

Never could get the hang of the barrel trimmer - ruined too many blanks because of the aggressiveness. Always needed sharpening.

gordon

StuartCovey

Member

I just use a regular barrel trimmer. Occasionally if its a soft wood or an acrylic that is prone to chipping I will use a mounted belt sander.

Thank you. I also use the lathe, scrap wood and transfer punch. However, I run into the following problems:

After spinning for about 5 seconds (at 1100) with 80 grit, the adhesive backing of the Diablo sanding disk paper heats up and and spins-off from the fast plate; it also leaves gummy residue on the wooden face plate created an uneven adhering surface.

I recently cleaned/lightly sanded my face plate and used the Abranet hook and loop sanding material. The hook and loop (Velcro) created a padded surface. After several separate attempts, I noticed that I was not getting a flat trimmed barrel surface. I was getting a slightly concave surface where the center (where the brass tube is located is higher than the surrounding barrel material area.)

Thoughts (please)?

Thank you.

After spinning for about 5 seconds (at 1100) with 80 grit, the adhesive backing of the Diablo sanding disk paper heats up and and spins-off from the fast plate; it also leaves gummy residue on the wooden face plate created an uneven adhering surface.

I recently cleaned/lightly sanded my face plate and used the Abranet hook and loop sanding material. The hook and loop (Velcro) created a padded surface. After several separate attempts, I noticed that I was not getting a flat trimmed barrel surface. I was getting a slightly concave surface where the center (where the brass tube is located is higher than the surrounding barrel material area.)

Thoughts (please)?

Thank you.

Last edited:

cal91666

Member

Tony, I had the same issue of the concave surface even using Rick Herrell's sanding mill and discovered that if I didn't apply as much pressure (rushing) and just let the sandpaper do its job things turned out a lot better.

I will figure this out. I have to find a strong, yet not too strong adhesive to "glue" the sp directly to the plate. I also slowed down my RPM to 800, and hit the blank for no more than 3 second lightly. We will see. Thank you and hope to see you at MAPG. I an eager to meet all of the fine folks!

JD Combs Sr

Member

Generally use a barrel trimmer but have occasionally used the lathe or a sanding disk on the lathe when the trimmer was dull and I didn't want to take time to sharpen it.

BruceA

Member

Carbide tipped barrel trimmer. Hundreds of blanks on that thing, and still works great.

Brian Frank

Member

I use my table saw with a crosscut sled to creep up on the brass tube. Then I use a barrel trimmer to square up the ends. A light touch using my drill press is all that is needed. I have seen some videos where the barrel trimmer was used to remove an 1/8" or more of the blank. Doing this I can see how things can get pretty explosive.

Ratimus

Member

I drill mine on the lathe, glue in the tube while the blank is still in the chuck, and face the blank square with a tiny little scraper. Then I flip the blank around and do the other side. Sometimes I use a forstner bit in place of the scraper if I think it's a good idea.

toddlajoie

Member

I use the barrel trimmer before turning, then after turning, I use the barrel trimmer with the head turned upside down on the 7mm shaft with self adhesive sandpaper on the back of the trimmer head to touch up and make sure it is nice and square after turning. This also helps take off any excessive CA or other finish that may be on the ends (I only do TBC for finishing, so the ends are not protected by bushings..)or take away the slight rounding that happens on the edges when you sand without bushings. Using the 7mm shaft and holding the larger diameter tube against the side works nicely to not use just a ring of the sandpaper. I roll the blank against the shaft as it sands also to help keep things even. The 7mm shaft is also just about the size of a standard hole punch so it's pretty easy to cut squares and punch the hole to get a nice patch of sandpaper.

I do have issues with some of the adhesive staying on the trimmer head when I have to change paper, but I just scrape it off, and if it gives me a hard time, a bit of acetone usually takes it off. You've found the drawback to any sort of soft base to the sanding surface, it needs to be solid to get a good flat and square edge.

I do have issues with some of the adhesive staying on the trimmer head when I have to change paper, but I just scrape it off, and if it gives me a hard time, a bit of acetone usually takes it off. You've found the drawback to any sort of soft base to the sanding surface, it needs to be solid to get a good flat and square edge.

longbeard

Member

Tony, i have lathe on the slowest speed and try to let the sandpaper to do work. At times the glue on the SP does release while i'm trimming the end but only after i've done a dozen blanks or so. I also use a blast of air to keep the SP clean from dust.

Harry

Harry

Would this work?

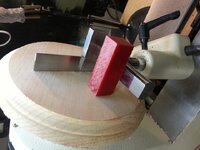

Ok...maybe I need to work less hours and stops taking 4 hour snaps Saturday afternoons. But why would this work? Imagine sand paper adhered to the disk, and stability of a larger tool rest/work table (6 x 6, or maybe leave is as is as long as it is flat and perpendicular to the disk) secured to the post. Assuming I want to trim a teenth from each side (with a brass tube in the barrel), would this work?

Ok...maybe I need to work less hours and stops taking 4 hour snaps Saturday afternoons. But why would this work? Imagine sand paper adhered to the disk, and stability of a larger tool rest/work table (6 x 6, or maybe leave is as is as long as it is flat and perpendicular to the disk) secured to the post. Assuming I want to trim a teenth from each side (with a brass tube in the barrel), would this work?

Attachments

Last edited:

philipff

Member

Years ago I started trimming the ends by chucking them up, using the tailstock/60d. to center perfectly, then a spindle gouge to take the wood down to metal. A brief touch of the sandpaper on a pad and a Perfect fit every time. Yes, it is a bit time consuming but I have plenty of that!

Curly

Member

Ok...maybe I need to work less hours and stops taking 4 hour snaps Saturday afternoons. But why would this work? Imagine sand paper adhered to the disk, and stability of a larger tool rest/work table (6 x 6, or maybe leave is as is as long as it is flat and perpendicular to the disk) secured to the post. Assuming I want to trim a teenth from each side (with a brass tube in the barrel), would this work?

In my opinion. Nope. You have no way of ensuring the tube in the square blank is perfectly centred in the blank when it was drilled and it is virtually impossible to get a perfectly square blank to start with either. So registering the blank from the outside will result in out of square ends when the pen is turned.

With a rod through the blank and it is perpendicular to the sanding disc you are assured the face will be sanded perpendicular to the axis of the tube no matter what shape the blank is.

You are right; I answered my own question after thinking about it and discussing with another member. Thank you for caring enough to set me straight. I looking forward to Rick's jig! Until then, it will be the barrel trimmer. Thanks again!

Argo13

Member

Tony,

I use Rick's Offset lathe sanding jig. I used a piece of Formica counter top attached to the face plate. I use 5" stick it 80 grit disk stuck to the Formica side. Spin at 1250 rpm and never had a problem with the glue. I do get some residue after changing to a new disk but it is pretty easily removed.

Jason

I use Rick's Offset lathe sanding jig. I used a piece of Formica counter top attached to the face plate. I use 5" stick it 80 grit disk stuck to the Formica side. Spin at 1250 rpm and never had a problem with the glue. I do get some residue after changing to a new disk but it is pretty easily removed.

Jason

Rink

Member

Decided the pen mill wa a little harsh for some blanks. have been using my stationary belt sander, with a combination square to keep the blank square to the belt. An upgrade would be a jig to square the TUBE to the belt!

KenV

Member

Tony -- I did some checking with the 12 inch disk sander and the 9 inch lathe MDF sandpaper disk and neither is quite dead on. However, if I slowly rotate the pen section while lightly feeding it into the sand paper, I get very very close to dead square on the average.

Rick Herrells little jig USED WITH HAND POWER ONLY does a nice job of cleaning up a few thousand and leveling off the end. After turning and finishing, I make one more pass with the Herrell hand sanding jig and am ready for polish and assembly.

Seems to work well. I can batch them to close and finish as I turn.

Rick Herrells little jig USED WITH HAND POWER ONLY does a nice job of cleaning up a few thousand and leveling off the end. After turning and finishing, I make one more pass with the Herrell hand sanding jig and am ready for polish and assembly.

Seems to work well. I can batch them to close and finish as I turn.

ljpilcher@suddenlink

Member

Barrel Trimming

I began with a barrel trimmer. Keeping it sharp was a problem. When doing a laser cut inlay blank that I could not use a barrel trimmer on, I made a jig with my face plate and sandpaper. Since then I have used both. The sanding jig of course just used the center of the paper and was extremely slow. With my barrel trimmer having seen better days, I have ordered Rick Harrell's offset jig. Can't wait to use it and say goodbye to the barrel trimmer.

I began with a barrel trimmer. Keeping it sharp was a problem. When doing a laser cut inlay blank that I could not use a barrel trimmer on, I made a jig with my face plate and sandpaper. Since then I have used both. The sanding jig of course just used the center of the paper and was extremely slow. With my barrel trimmer having seen better days, I have ordered Rick Harrell's offset jig. Can't wait to use it and say goodbye to the barrel trimmer.

Cavediver

Member

Tony,

Use some melamine or something similar for your sanding disc. It's more or less impervious to solvents, so cleaning off the remaining adhesive won't be as difficult and it won't ruin the disc every time. If you don't have access to melamine, drop me a line and I'll knock a couple of discs out for you.

Use some melamine or something similar for your sanding disc. It's more or less impervious to solvents, so cleaning off the remaining adhesive won't be as difficult and it won't ruin the disc every time. If you don't have access to melamine, drop me a line and I'll knock a couple of discs out for you.

BSea

Member

I agree. I round my blanks to fit into a collet chuck, and use my parting tool to flush trim the blank to the tube. Perfectly square everytime, and I've never blown a blank using this method. Plus it's really fast if your doing them in batches.Almost all of the above.

The best 'other' that on aware of is trimming the ends on the lathe using a turning tool. Very solid method.

Just 1 of the many uses for a collet chuck.