glycerine

Member

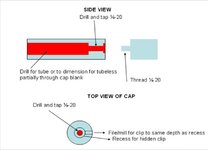

For those of you who turn custom finials, not just the finial inserts, how are you doing it? Are you making them threaded or are you turning them to the exact size so they will press fit in?

What I mean is the end caps that make the clip look like it is recessed/hidden, but you can still tell that the end cap is actually a separate piece. I'm asking mostly for the Gent/statesmen type kits, not the europeans that I know are threaded... Sorry, I don't have any example pics though I have seen several in posted photos...

What I mean is the end caps that make the clip look like it is recessed/hidden, but you can still tell that the end cap is actually a separate piece. I'm asking mostly for the Gent/statesmen type kits, not the europeans that I know are threaded... Sorry, I don't have any example pics though I have seen several in posted photos...