wizard

Member

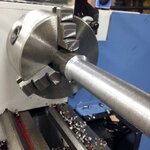

I was just wondering if anyone can give me any hints on how to turn Koftgari Damascus. Ordered what I thought was 14 mm diameter rod and ended up with a rod 41 mm in diameter.  So far turning this down to diameter has been a slow process and I've gone through two carbide blades...and..yep lol all three sides of each cutter :redface:. Any help would be appreciated.

So far turning this down to diameter has been a slow process and I've gone through two carbide blades...and..yep lol all three sides of each cutter :redface:. Any help would be appreciated.

Doc

Doc