satchm0h

Member

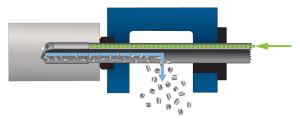

So, I was drilling this blank to try my hand at a Kate Harrow hobby knife. It's a long blank, so I went pretty much all the way in. I stopped the lathe, unlocked my tail stock and started removing the bit. That is when it just stuck in place. I think I let the bit get too hot and it seized up. When I turned on the lathe, it would not spin and just errored. I tried vice grips on the bit and channel locks on the blank, but the vice grips just spin on the round bit shank. I put the drill chuck in the headstock, and turned down the end a bit and can see the drill bit about a quarter inch from the end.

I know I can just turn the acrylic off the bit, but was hoping to salvage the blank. Any thoughts? Maybe a torch to heat up the bit?

Thanks in advance,

~ted