amtechrs

Member

Hello all,

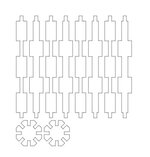

I'm fairly new to pen turning (actually any lathe work). Definitely have the bug! I've initially used hybrid blanks that I've poured, using brown or red malee(?). I recently started using my laser cutter to make pen blank 'boxes'. There's a very cool website for laser users that helps you make all kinds of boxes and other things, it's https://www.festi.info/boxes.py/ . I love that site. Anyway, I make the box/blanks according to specific pen dimensions, and embellish in different ways. I'm still experimenting! Here are some pictures of a few finished pens, and some of boxes in progress. I look forward to learning a lot from this group!

Best,

Richard

I'm fairly new to pen turning (actually any lathe work). Definitely have the bug! I've initially used hybrid blanks that I've poured, using brown or red malee(?). I recently started using my laser cutter to make pen blank 'boxes'. There's a very cool website for laser users that helps you make all kinds of boxes and other things, it's https://www.festi.info/boxes.py/ . I love that site. Anyway, I make the box/blanks according to specific pen dimensions, and embellish in different ways. I'm still experimenting! Here are some pictures of a few finished pens, and some of boxes in progress. I look forward to learning a lot from this group!

Best,

Richard