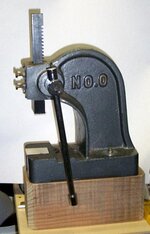

Ok So I buckled and got an arbor press after listening to all you guys talk about them, but now what I am wondering is how put the piece together? I guess what I wanna know is do most of you guys put the pieces together by free hand or is the bottom piece mounted on something? I also was hoping that of you turners out there that do use a press, would you be willing to post a picture of yours so I could see the set ups! I have dont my fair share of browsing on the forum, but I just figured it would be easiest to ask for some pictures!

Thanks

Thanks

![DSCF0005 [640x480].JPG](/data/attachments/4/4154-826743a0dd8907b7d834bbcbea1d0251.jpg?hash=gmdDoN2JB7)