Eric

Scroll chucks and Cole jaws are one class of products. Lathes are another. They work together, but the range of use of one product may exceed the range of use of a different product.

My first lathe was a small (7x12) minilathe. I bought a PSI Utility Chuck that came with Cole jaws to use with it - and found that the throw dimension on the lathe limited how far I could expand the Cole jaws. And the problem wasn't limited to using the jaws at its largest diameter on larger bowls. As you know, the buttons on Cole jaws can be inserted at a variety of radiuses up to whatever is the maximum for the jaws, but because the jaws couldn't open fully, the range of application of every button position was limited. That was a bummer, but I marked it up to the fact that my minilathe was intended for turning pens and other small items, while the chuck and its associated Cole jaws were intended for the use in making bowls and other larger stuff. Eventually, I sold the minilathe and bought a 12" Turncrafter whose capabilities were a close match to the chuck and Cole jaws.

PSI does offer a small set of Cole jaws that might be more compatible with your lathe, but my advice would be to not go that route - you are likely to upgrade to a larger lathe (and perhaps sooner than you expect), so do make a purchase now that will have limited use later on.

It would not be difficult to make your own Cole jaws sized to match your lathe, and you could probably do this for less than $50, and even less if you already have some of the materials. If you keep the investment low, the fact that the jaws might be less useful if you upgrade to a larger lathe will be less painful. Use 1/2" cabinet-grade birch plywood for the jaws, and t-nuts to attach the buttons. Note that the machine screws that hold the buttons must match the t-nuts, but don't have to have the same threading as the machine screws that attach the jaw plates to the chuck slider (on Barracuda chucks, the slider screws are metric). Make the four jaws as a solid plywood circle, locate and drill holes for the mounting screws and t-nuts before cutting the circle into four quadrants.

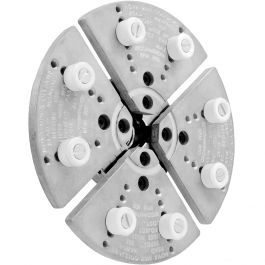

PSI's 'C' Cole jaws use pins that are essentially cap screws with a flat-sided rubber sleeve. There are other brands (that probably won't match Barracuda chucks) that have rubber buttons with a dovetail profile that probably grip better because they conform to the shape of the bowl being turned. Commercial Cole-jaws are designed to use eight pins or buttons, and are designed to be used at a maximum of 600 r/min. Most turners also try to use tailstock support as much as possible when using Cole jaws. I think it should be possible to get away with only four dovetail buttons provided they are made of rubber, and provided that standard usage precautions are followed - especially when using the jaws to hold smaller-diameter turnings. However, that is a safety issue so the choice to take that step must be left to the user.

Finally, if you are doing really small work, it is possible to make up a set of buttons that attach directly to the sliders on your chuck, eliminating the plate altogether. Again, be aware that you would need machine screws that match the threading on the chuck sliders (on my "C" utility chuck, the slider screws are M5-0.8).