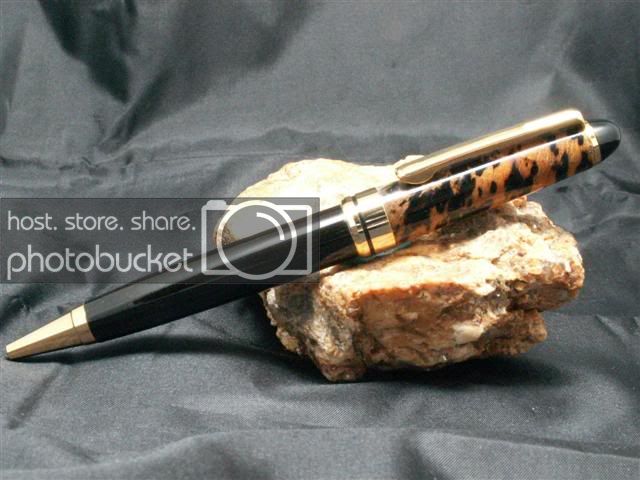

I'm trying to turn a pen out of banksia. (the tree, not the pod).

I've never tried a CA finish on this material before, and I don't know if I ever will try again.

Unfortunate, cause it's really nice stuff....kind of like lacewood, but much tighter grain, and purplish.

I've done CA with african blackwood, nigerian ebony, (the ones that usually present a problem) I even did a CA pen with teak once successfully. A little lacquer thinner to break up the oils, and then quickly some thin CA to seal up those oils.

For the life of me, I can't get this banksia to get to the final stage without looking hazy.

I sand from 240 -800 silicon carbide.

Wipe down with lacquer thinner.

Then plenty of coats of CA.

Then 600-2500 silicon carbide, leaving no high spots or previous scratches.

Then 6000-12000 MM.

Then plastics polish.

Then Renaissance Wax.

I get through the plastics polish step, and I just can't get the haziness removed.

I've spent probably an hour and a half just on the finish stage of this pen.

I've given up. It's still on the lathe, and I figure that a good night's sleep will give me better perspective.

Right now, I'm just thinking that tomorrow I'll sand it down to bare wood, and just buff and wax...not my favorite finish, and it'll be a shame not to see the chatoyance that a good CA finish could give this wood, but alas...

Ever have a pen that you just won't take a CA finish? Any suggestions are VERY welcome.

I've never tried a CA finish on this material before, and I don't know if I ever will try again.

Unfortunate, cause it's really nice stuff....kind of like lacewood, but much tighter grain, and purplish.

I've done CA with african blackwood, nigerian ebony, (the ones that usually present a problem) I even did a CA pen with teak once successfully. A little lacquer thinner to break up the oils, and then quickly some thin CA to seal up those oils.

For the life of me, I can't get this banksia to get to the final stage without looking hazy.

I sand from 240 -800 silicon carbide.

Wipe down with lacquer thinner.

Then plenty of coats of CA.

Then 600-2500 silicon carbide, leaving no high spots or previous scratches.

Then 6000-12000 MM.

Then plastics polish.

Then Renaissance Wax.

I get through the plastics polish step, and I just can't get the haziness removed.

I've spent probably an hour and a half just on the finish stage of this pen.

I've given up. It's still on the lathe, and I figure that a good night's sleep will give me better perspective.

Right now, I'm just thinking that tomorrow I'll sand it down to bare wood, and just buff and wax...not my favorite finish, and it'll be a shame not to see the chatoyance that a good CA finish could give this wood, but alas...

Ever have a pen that you just won't take a CA finish? Any suggestions are VERY welcome.